Real-Time Thermal Rating

Real-Time Thermal Rating (RTTR), also known as Dynamic Cable Rating (DCR), is an advanced technology designed to optimize the performance and safety of power grids. It calculates the real-time temperature of power cable conductors by factoring in current load, load history, and thermal conditions. This enables grid operators to run transmission lines and distribution networks at higher capacities, without compromising safety.

How RTTR Works

RTTR uses precise thermal models based on industry standards such as IEC 60287, IEC 60853 and CIGRE TB 640. These models consider the environmental conditions around high-voltage cables, calculating conductor temperature profiles and forecasting maximum permissible loads in both steady-state and emergency conditions. Using fast Kalman Filter technology, RTTR provides real-time data on the cable’s capacity, allowing utilities to maximize their grid’s performance.

Key Benefits of RTTR

RTTR offers significant advantages that make it an essential solution for modern load management of HVAC & HVDC underground and submarine cables.

Maximized Grid Capacity

Operate power grids closer to their thermal limits while maintaining safety, ensuring the maximum throughput of electricity.

Enhanced Safety and Reliability

RTTR continuously monitors conductor temperatures and triggers alerts when critical thresholds are approached, preventing overheating and potential failures.

Accurate Emergency Management

In critical situations, RTTR predicts the time and current required for cables to reach maximum temperature, helping operators respond effectively.

Reduced Maintenance Costs

With predictive capabilities, RTTR helps identify load patterns and optimize maintenance schedules, reducing operational costs and prolonging the life of infrastructure.

Seamless Integration

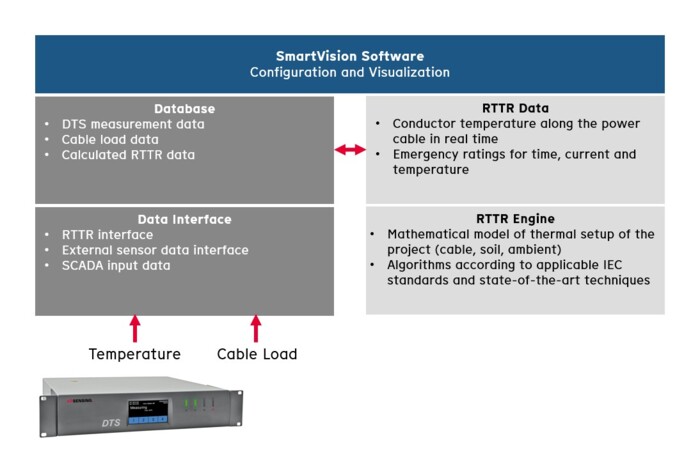

RTTR integrates with AP Sensing's SmartVision software, enabling seamless monitoring and communication with operator load dispatch centers via standard protocols such as Modbus TCP, IEC 61850, and IEC 60870-104.

Cutting-Edge Product Features & Highlights

Conductor Temperature Profiles

Real-time monitoring of temperature along the entire length of power cables using Distributed Temperature Sensing (DTS) and load data.

Steady-State Ampacity Calculation

Using continuous temperature measurements from the cable (internal or external fiber optic sensor) and available load data, RTTR accurately calculates the conductor core temperature.

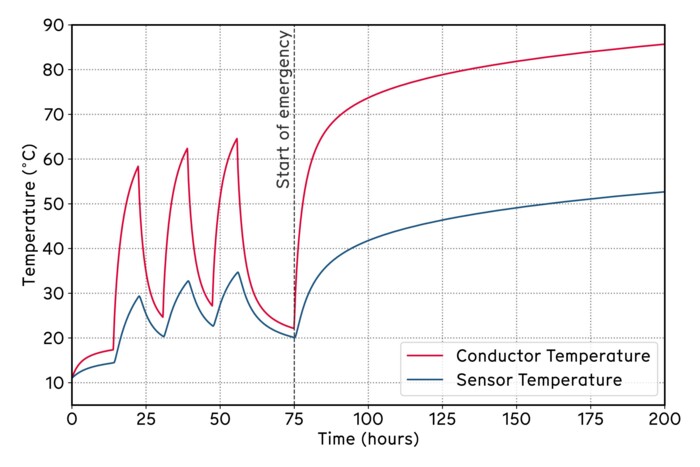

Emergency Ratings

The RTTR engine can predict:

- Future cable temperatures, up to one week in advance

- The time required for the cable to reach its specified temperature limit

- The maximum current the circuit can safely carry before reaching the specified temperature

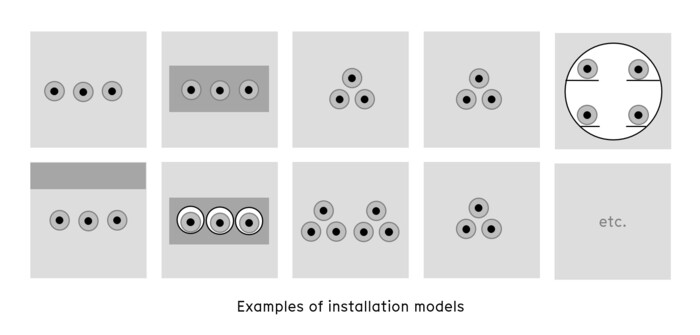

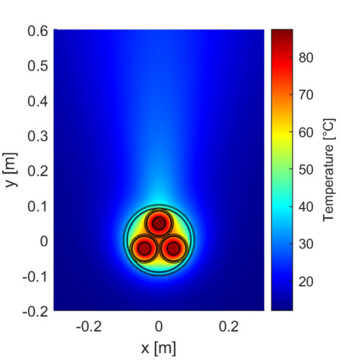

Advanced Thermal Modeling

Supports a wide variety of cable designs (single-core, three-core, sheathed, composite cables, and concentric neutrals). Numerous cable-laying conditions can be modeled, such as directly buried, duct banks, thermal backfills, buried ducts and pipes, submerged cables, and many more.

The cable phases can be touching or non-touching, single or multiple circuits installation combined. AP Sensing’s RTTR solution can model several materials with individual thermal parameters, for example stratified soil layers, multiple duct banks and thermal backfills. The model range is continually being extended.

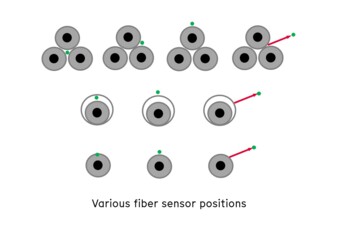

Various Types of Fiber Positions

verified by Finite-Elements-Method (FEM) simulations can be covered:

Versatile Applications of RTTR Technology

Transmission Cables

Optimize the performance of HVAC and HVDC power transmission lines, both underground and submarine.

Distribution Networks

Improve the reliability of distribution systems by dynamically managing load limits based on real-time temperature data.

Renewable Energy Integration

Support the integration of renewable energy sources by optimizing cable capacity in response to fluctuating energy supply.

Critical Infrastructure Monitoring

RTTR identifies potential problem areas in the grid, providing early warnings to prevent failures in critical infrastructure.

AP Sensing’s RTTR solution empowers utilities with the data and tools needed to maximize efficiency, improve safety, and reduce costs across power grids.