A Linear Heat Detection (LHD) system is designed to monitor and detect changes in temperature along the length of a sensor cable. A fiber optic LHD uses standard fiber optic sensor cables, typically over lengths of several kilometers, that function as linear temperature sensors. These systems are truly distributed, i.e. respond to heat at any point along the cable equally. The result is a continuous temperature profile along the entire length of the sensor cable.

Fiber optic Linear Heat Detection (LHD) systems monitor and detect temperature changes along the length of a sensor cable, typically spanning several kilometers. Utilizing certified fiber optic LHD cables as continuous temperature sensors, this system responds to heat at any point along the cable, detecting hotspots and fires with remarkable precision. Over a length of 10 km, for example, the system can measure 10,000 temperature points every 5 seconds, offering rapid detection and precise information on fire location, size, and spread. By providing vigilant and continuous temperature monitoring across extensive distances, fiber optic LHD enhances fire safety for a wide range of critical infrastructure, including traffic and utility tunnels, car parks, conveyors, cable trays, solar farms, and battery storage systems.

How Linear Heat Detection Works

A fiber optic Linear Heat Detection system essentially consists of the interrogator unit and the sensor element, i.e. the fiber optic sensor cable itself. By utilizing a single optical fiber within a sensor cable, LHD provides measurement of temperature and monitoring of changes at every point along the entire cable length in real-time. It detects hotspots and fires, triggering the fire alarm or suppression systems and providing precise information on fire location, size, temperature, and spread over several kilometres.

Enhance Temperature Control Using Raman Reflectometry

The LHD measurement principle is based on the Raman effect. An optical laser pulse emitted from the LHD interrogator travels through a single optical fiber. Light is scattered back to the transmitting end by interaction with the glass molecules, carrying temperature information along the route of the sensor.

The position of the temperature reading is determined by the arrival time of the returning light pulse (time of flight), analogous to radar echo analysis. With one single, passive fiber optic cable, the temperature of an entire asset is monitored continuously.

AP Sensing’s patented code correlation technology enables outstanding system reliability and accurate measurements over long distances with fine spatial resolution and short measurement times.

Unlike conventional methods that use single optical pulses to measure temperature distribution along the fiber, this technology leverages defined sequences of pulses (codes) to deliver significantly more probing energy into the fiber. This leads to a substantial boost in the Raman backscatter signal returning to the detector, significantly improving the signal-to-noise ratio (SNR). Mathematical deconvolution of the detector signal restores the full spatial resolution, determined by the length of a single bit of the code rather than the whole code length.

Eager to learn more about how LHD, also known as Raman Reflectometry, works? What role does backscattering play, and how are temperature locations determined? Watch our video to find out more about the main work principles here.

Benefits & Advantages of Linear Heat Detection

Linear Heat Detection offers many advantages for fire detection applications, including:

Extended Coverage Capabilities and Continuous Monitoring

A single fiber optic LHD cable can cover long distances, eliminating the need for multiple sensors or multiple linear heat detectors, and providing a cost-effective solution that efficiently monitors large areas. Additionally, fiber optic LHD systems, remain consistent over the entire length, ensuring reliable monitoring across extended areas.

High Sensitivity and Temperature Resolution

Fiber optic LHD offers precise sensitivity and temperature resolution due to its ability to measure temperature changes along the entire length of the fiber. This sensing capability allows for more accurate and responsive monitoring solution than other thermal detection systems which may have limitations in detecting subtle temperature variations, potentially leading to delayed heat detection.

Precise Event Localization

Linear Heat Detection systems locate and pinpoint the exact location of temperature changes, hotspots, or fire events down to below -0.5 meter spatial resolution (e.g. AP Sensing’s LHD N45-Series). This provides accurate and quick information on the location, size, and spread of a fire, with pre-alarms, which can give operators early indication of upcoming problems at specific locations or areas, and early intervention measures aiding in rapid responses for fire prevention or suppression.

Versatility & Effectiveness in Harsh Environments

Fiber optic LHD systems use fiber optic cables as a sensors, which are immune to electromagnetic interference. This makes the sensing solution suitable for a wide range of harsh surroundings including dirt, dust, corrosion, humidity, extreme temperatures and temperature changes, radioactivity and solvent vapors. Additionally, LHD systems are adaptable to varying installation requirements and usually integrate with existing fire alarm systems to immediately trigger alarms, activate trigger sprinkler systems, or send notifications to relevant personnel.

Low Maintenance Requirements and High Reliability

Fiber optic LHD systems inherently require minimal maintenance. Exceptionally high reliability is ensured thanks to the outstanding quality of the instruments, such as AP Sensing's LHD N45 series with an annualized failure rate (AFR) of only 1%. In addition, the fiber optic cables used are purely passive and durable, with a long lifetime, ensuring reliable performance over time. This is particularly invaluable for areas difficult or impossible to reach, providing a guarantee of long-term, maintenance-free operation.

Smart Alarm Configuration

In many fire detection applications, reliable protection can be enabled with maximum thresholds, temperature gradients or temperature differences to average. Depending on the environmental conditions and the expected critical thresholds, these parameters can be set and tweaked individually per detection zone to reach maximum fit for the application needs. Fiber optic Linear Heat Detection allows smart alarm configuration with up to 2,000 zones per sensor channel, which is beneficial especially for large-scale infrastructures, where the sensor cable typically runs through different areas under various temperature conditions. Read more here

System Redundancy

A Linear Heat Detection system comprises two elements, the sensor cable and the LHD interrogator. Depending on the configuration, monitoring can continue even in the case of a break of the sensor cable, e.g. due to damage from construction works or other accidential or deliberate interference. For highest requirements on system redundancy, different configurations of the sensor cable and interrogator are possible.

Use Cases of Linear Heat Detection

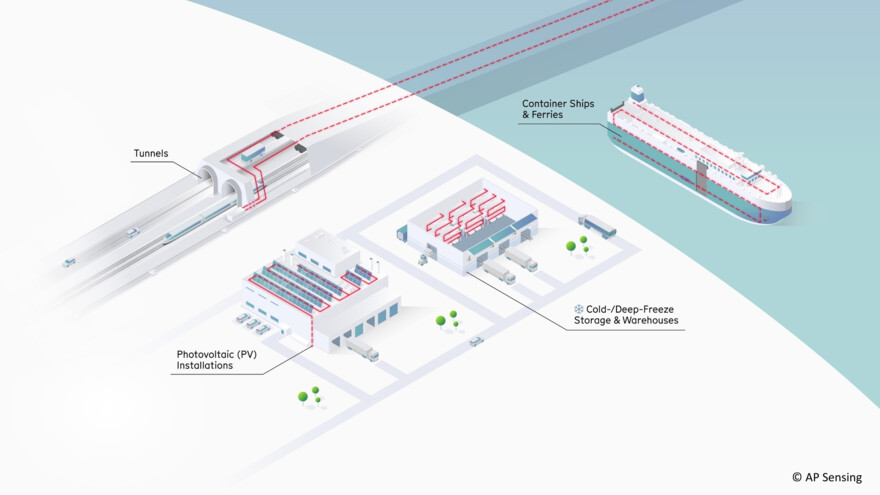

Fiber optic LHD systems are versatile and offer maximum reliability, even under severe conditions. Therefore, these systems are used in a wide range of applications, where accurate fire detection is needed. They are particularly beneficial in special hazard areas, where a fire can have devastating consequences and causes risk to human life, damaged infrastructure, and long downtimes.

Some of the key applications of Linear Heat Detection systems include:

- Road, rail and utility tunnels, as well as car parks

- Conveyor belts

- Cable trays and transformers

- Tank farms and coal storage

- Refineries, chemical plants and power plants, including NPP

- Production areas, warehouses and food processing facilities

- Photovoltaic (PV) installations, e.g. in solar farms (greenfield & rooftop)

- Battery storage power stations

- Ships & vessels

- Photovoltaic (PV) Installations

- Battery Energy Storage Systems

- Cable Trays and Transformers

- Production Areas

- Food Industry

- Warehouses and Freezers

- Conveyor Belts

- Tank Farms and Coal Storage

- Power Plants

- Refineries and Chemical Plants

Comparison of Linear Heat Detection Systems

Compared to other fire detection methods, fiber optic LHD offers many advantages. A fiber optic based LHD solution detects fires or hotspots quickly and precisely identifies their location within a few meters. In addition to the advantages mentioned above, the benefits of fiber optic LHD in direct comparison with conventional LHD systems (including analog, digital and multipoint LHD) are as follows:

Fiber Optic LHD | Multipoint LHD | Analog LHD | Digital LHD | |

| Lightweight Cable, Simple Installation | ||||

| Simultaneous Detection of Multiple Events | ||||

| Resettable Detector | ||||

| Flexible Alarm Parameters | ||||

| Flexible Zoning | ||||

| Gapless Temperature Measurements |

AP Sensing's LHD system

LHD N45-Series

With the third generation of our LHD system, the N45-Series, AP Sensing is raising the standard for fiber optic LHD. The N45-Series is certified to national and international standards for fire detection, offering the longest certified range on the market. No other fire detection system can withstand temperatures up to 750 °C (1400 °F) without losing monitoring capabilities.

Fiber Optic Sensor Cables

Our solution also includes certified, easy to install and maintenance-free sensor cables to fit your requirements. These completely passive cables are inherently safe against electromagnetic interference (EMI) and withstand operating temperature from – 40 up to +85 (150) °C.

Key Takeaways

Linear heat detection systems represent a significant advancement in fire safety technology. By offering continuous heat detection along the entire length of a sensor cable, these systems provide a level of precision and reliability that traditional fire detection methods struggle to match. They are resistant to harsh conditions and electromagnetic interference, making them suitable for a wide range of applications. Furthermore, with regular testing and maintenance, these systems can offer years of reliable service.

Fire safety is a critical concern that demands utmost attention. With technological advancements, tools like Linear Heat Detection systems provide significant reassurance.. These systems represent an important step forward and make a valuable contribution to fire protection.

With a proven track record and continued innovation, AP Sensing offers a completely integrated, end-to-end solution made in Germany. Our team works together with you to select the right combination of technologies to fit your requirements.

Frequently Asked Questions

What Factors Influence the Response Time of a Linear Heat Detection system?

While the measurement time of an LHD system is exclusively a parameter of the interrogator unit, the response time of a fiber optic linear heat detector is determined and influenced by a multitude of parameters. These include the thermal behavior of the sensor cable, the cable installation method, the alarm parameter configuration, the fire type, the heat release rate (HRR) and environmental conditions such as wind speed. The thermal behavior of the sensor cable plays a special role here since it determines the response behavior of the overall system to a predominant extent and not—as is often erroneously assumed—the measurement time of the interrogator unit.

Are There Any Disadvantages to Configuring a Small Spatial Resolution When Using Fiber Optic LHD?

A smaller spatial resolution typically results in higher noise levels, while a wider spatial resolution smoothens a temperature trace and reduces statistical uncertainty of measurements, hence improving the temperature resolution and consequently false alarm resilience. Considering the real world and real fire situations, normally a spatial resolution as low as one meter is more than sufficient, often a larger resolution of two or even four meters is preferential.

What Role Does System Configuration and Redundancy Play in LHD Reliability?

The reliability of a fiber optic Linear Heat Detection (LHD) system can be positively influenced not only by design, component selection, and intensive testing, but also by clever setup and use of the system itself. In this way, fault resilience is achieved in both system components as well as the overall system.