SmartVision Alarm Management

How the Alarm Management Works

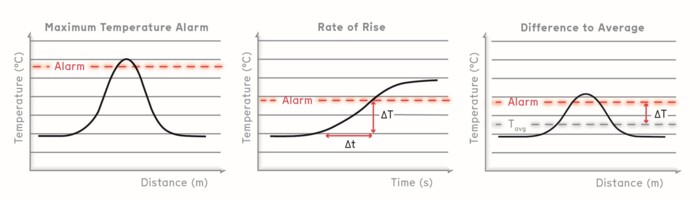

In various applications like fire detection, basic thresholds for maximum temperature, temperature gradients, or differences to average temperatures enable reliable protection. These parameters can be customized per detection zone depending on environmental conditions and expected critical thresholds, ensuring a precise fit for each application.

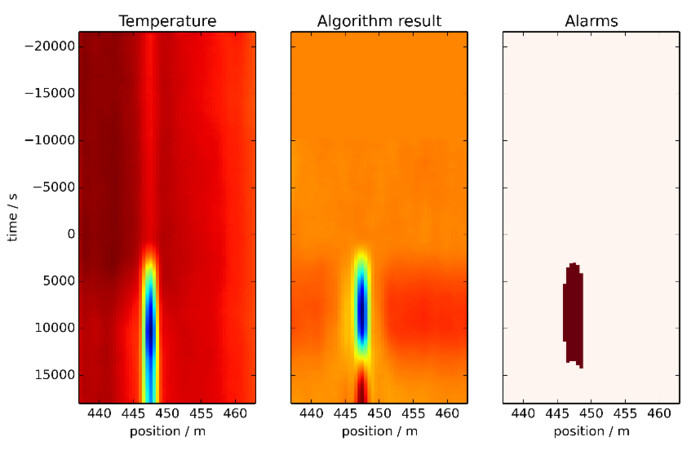

AP Sensing's proprietary SmartAlarm system goes beyond basic methods. Through collaboration with field experts, SmartAlarm utilizes sophisticated algorithms capable of detecting smaller anomalies, such as leaks, even in environments where ambient conditions fluctuate, or the anomaly itself doesn't generate a significant temperature change. Algorithms adjust based on site-specific conditions, reliably raising alarms for local events that standard systems may miss or incorrectly flag.

These algorithms also assess historical temperature variations and trends across the entire asset, capturing environmental temperature influences in real time. This allows SmartAlarm to distinguish between normal ambient changes and abnormal events like leaks, ensuring accurate detection even under the most challenging conditions.

For certain scenarios, further analysis based on machine learning algorithms is required and these can be applied to DTS, DAS and DTSS systems. The DTS machine learning algorithms analyze historical temperature variations over the entire asset and are trained to distinguish between typical and abnormal asset behavior. This for example enables the detection of unusual events along a power cable, such as local free spans in subsea cables or small hotspots caused by local damage. DAS machine learning allows the detection of various events, e.g. digging, drilling, anchor drops, vehicles in proximity and others.

Benefits & Advantages of SmartAlarm Monitoring

The SmartAlarm module offers numerous benefits that improve operational efficiency and safety:

Enhanced Accuracy

SmartAlarm’s ability to differentiate between normal and abnormal events ensures more reliable detection, minimizing false alarms.

Customizable Settings

Adjust thresholds and alarm configurations for each detection zone to optimize monitoring and reduce maintenance needs.

Predictive Maintenance

Early detection of anomalies enables proactive response, reducing costly downtime and repairs.

Seamless Integration

Adaptability

Capable of handling fluctuating conditions and environmental changes, ensuring continuous monitoring under diverse scenarios.

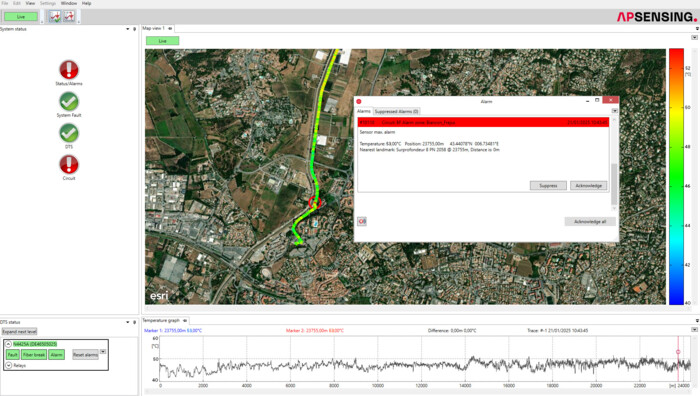

Comprehensive Alarm Configuration for Tailored Monitoring

Advanced Asset Alarm Management for Customized Monitoring and Control

- Configuration of alarm zones and polygonal asset zones along the monitored asset

- Thresholds and alarm types per zone

- Transmission of alarms to peripheral equipment or superordinate management systems (SCADA)

- Alarm handling such as acknowledgement, history and exporting

- Lists of all connected instruments with system status and connectivity monitoring

- Further capabilities based on the client’s needs

Versatile Use Across Critical Infrastructure

Power Cable Monitoring

SmartAlarm monitors temperature variations along power cables, detecting faults and preventing overheating to ensure reliable power transmission.

Pipeline Monitoring

Early warning for leaks, temperature fluctuations, and external threats like excavation or drilling near buried pipelines.

Geothermal Monitoring

SmartAlarm monitors temperature fluctuations in geothermal systems, ensuring early detection of faults and optimizing the efficiency and safety of geothermal energy production.

Railway Monitoring

SmartVision enhances railway safety and operational efficiency by continuously monitoring track integrity, train tracking, and vibrations. The system provides real-time alarms for potential hazards such as track buckling, broken rails, or third-party intrusion. Historical trend analysis further helps identify patterns and improve long-term railway maintenance and safety.

Conveyor Belt Monitoring

SmartAlarm ensures real-time detection of overheating, misalignments, and equipment faults in conveyor belts, helping to prevent damage and reduce downtime.

By leveraging SmartAlarm’s customizable, real-time monitoring capabilities, industries can ensure safety, operational efficiency, and proactive management of their critical assets.