Machine Learning Transient Alarm

The Machine Learning Transient Alarm (MLTA) leverages machine learning algorithms to accurately detect and alarm on abnormal temperature events, hidden among regular thermal fluctuations. The MLTA provides significant benefits in the monitoring of pipelines and power cables, ensuring early detection of critical leaks and hot spots.

Revolutionary Thermal Fingerprint Technology for Precise Temperature Monitoring

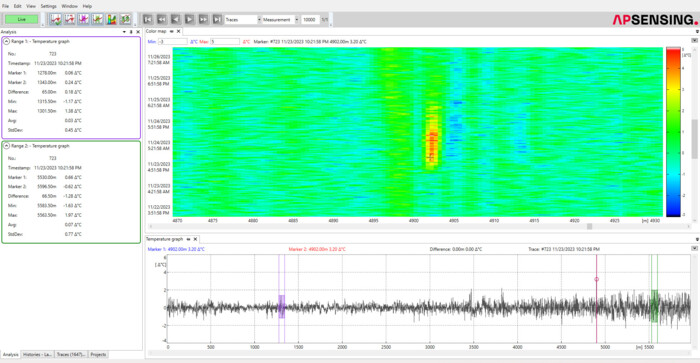

The MLTA module is designed to recognize subtle changes in temperature that would typically be obscured by normal operational variations. This innovative module generates a "thermal fingerprint" for each asset, accounting for typical temperature fluctuations caused by operational factors, such as product flow or load changes, diurnal temperature variations, or non-ideal sensor cable deployments.

Unmatched Sensitivity and Reliability for Long-Distance Temperature Sensing

MLTA for Pipelines

Pipelines often experience significant temperature variations during regular operation, which can mask the early signs of small leaks. With the MLTA module, these temperature anomalies can be more easily identified and reported.

Improved Detection of Small Leaks

MLTA enhances the system's ability to identify small cold or hot spots, typically undetectable during normal pipeline operation.

Precise Location of Temperature Events

The system pinpoints the exact location of abnormal temperature events, reducing response times.

Isolation of Normal Thermal Transients

By accounting for normal temperature changes, the system reduces false alarms, ensuring greater accuracy.

Faster Alarm Notifications

Leaks and temperature deviations are detected and reported more quickly, allowing operators to act before major damage occurs.

MLTA for Power Cables (Buried and Sea Cables)

Power cables, particularly those used in renewable energy systems, are vulnerable to hot spots caused by dynamic load fluctuations and other factors. The MLTA ensures these critical areas are detected early to prevent costly failures.

Early Detection of Hot Spots

Identifies small, localized overheating areas that can lead to significant damage if left undetected.

Accurate Identification of Abnormal Temperature Events

MLTA isolates unusual temperature increases, distinguishing them from normal load fluctuations.

Minimizing False Alarms

By isolating typical thermal transients, the module reduces the likelihood of false positives.

Advanced Features of the MLTA: Intelligent Detection for Critical Assets

Comprehensive Solutions for Power Cable Monitoring and Pipeline Monitoring

Power Grid Monitoring (Buried and Sea Cables)

Dynamic load variations, especially in renewable energy sectors like wind farms, can lead to undetected hot spots. The MLTA offers precise detection of overheating points, protecting cable integrity and preventing costly failures in power grids.

Pipeline Monitoring

Temperature fluctuations caused by product flow changes, start-stop operations, and environmental factors make small leaks challenging to detect. The MLTA helps operators spot even minor leaks quickly, minimizing environmental damage and reducing repair costs.

By leveraging MLTA industries can ensure safety, operational efficiency, and proactive management of their critical assets.