Project Overview

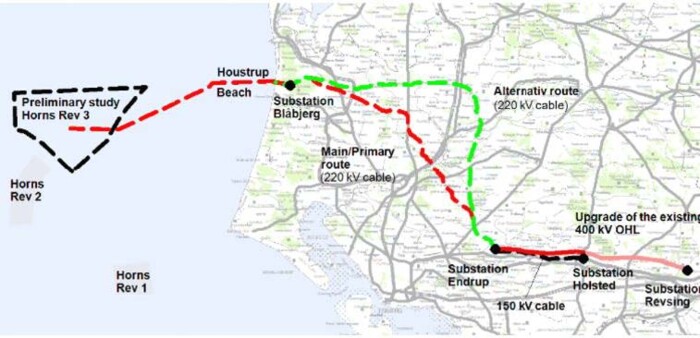

The Horns Rev 3 offshore wind farm, located off the west coast of Denmark, has a maximum installed power capacity of 400 MW. The operators wanted a monitoring solution to locate cable faults immediately after they occur. They chose AP Sensing for our unique combination of Distributed Temperature Sensing (DTS) and Distributed Acoustic Sensing (DAS) capabilities. Horns Rev 3 is Denmark’s 3rd offshore wind farm. AP Sensing’s solutions monitor the offshore transformer platform itself as well as a 220 kV offshore power cable of 36 km length from the platform to the transition joint located onshore and then to the substation Blåbjerg. Additionally, a 45 km long, 220 kV underground land cable from the substations Blåbjerg to Endrup is monitored.

Solution

Loose tube fiber optical cables with 4 x 12 G 652 D single-mode fibers and 1 x 6 OM 3 multi-mode fibers were installed. At the subsea section, the sensor cable is located inside the three phase subsea cable, which is buried 1 m below the seabed. At the land section, the sensor cable is located in a Ø 40 tube close to the center single-phase cable, which is buried 14 m below the surface.

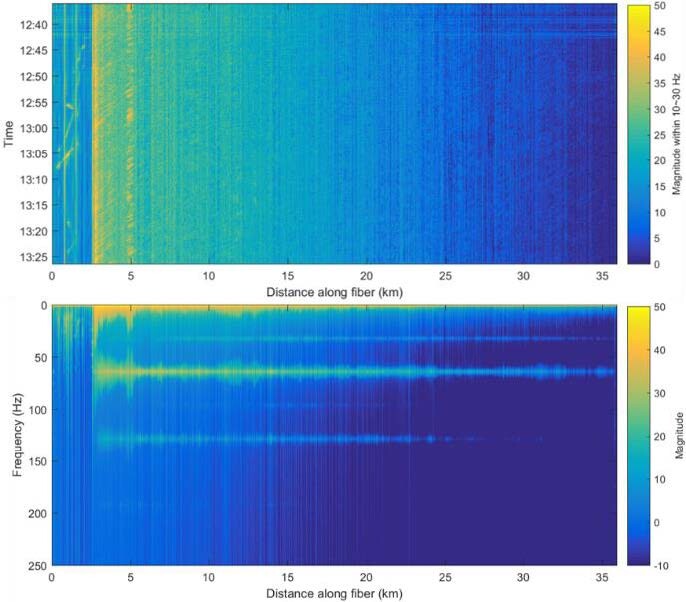

DAS for Power Cable Monitoring

The optical fault locating system is based on Distributed Acoustic Sensing technology. The DAS system detects acoustic signals that may be generated by a fault or in or near the high voltage cable. The vibrations that are produced by a fault are impulsive, broad in distance, and occur typically in the low frequency range. The DAS system is configured to monitor the power cable in real time, visualize the acoustic energy over time/distance in waterfall plots, and store the measured data. The system is additionally configured to alarm fault events and visualize the alarms in SmartVision.

Units

The optical fault location system consists of three DAS systems, including a single channel DAS interrogator, a DAS data acquisition unit, and a storage unit each. Two DAS units are located in Blåbjerg and one in Endrup. All have a 40 km measurement range. The temperature monitoring system consists of two DTS units. The first is in Blåbjerg with two channels and a 50 km measurement range. The other DTS unit is located in Endrup with four channels and a 30 km measurement range. The free channels are allocated for upcoming projects.

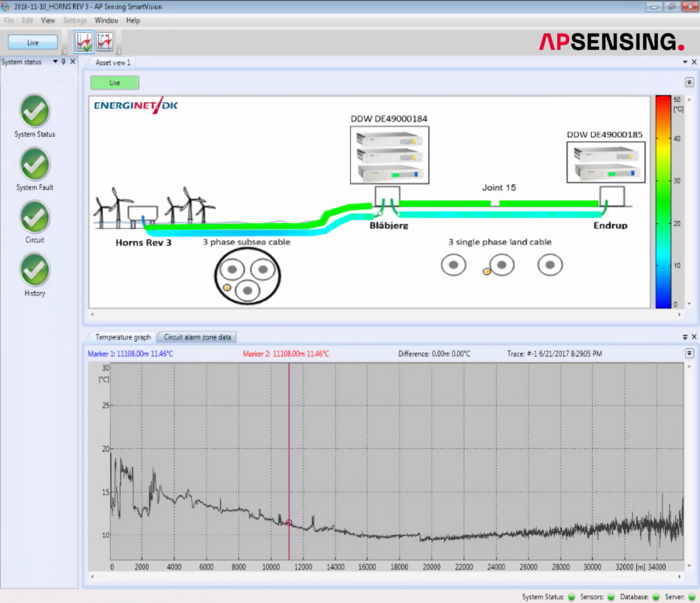

SmartVision

AP Sensing’s proprietary asset visualization software, SmartVision, provides multiple operators at multiple locations with a graphic overview of all temperature and acoustic information for their critical infrastructures. The main user interface for SmartVision is located at the Endrup substation. The software tool collects the temperature data in real time from the two DTS devices and the alarms from the 3 DAS devices, providing the user with a combined overview of both systems. Using the IEC 60870 5 104 protocol, SmartVision accesses the client’s SCADA/DCS platform to retrieve and share system and alarm status information. Operators can also switch between different projects integrated by AP Sensing with the SmartVision supervisor functionality installed on the main server at Energinet’s head office.

Conclusion

AP Sensing’s experienced project engineering team accompanied both pre-energizing test phases of the land and subsea power cable sections. The entire system has performed as expected since the completion of the installation and plans were immediately underway for future projects. AP Sensing has sold many further DTS and DAS units to the customer and won a framework agreement for further projects. Both of these exemplify the level of customer satisfaction with AP Sensing’s systems.