Project Overview

A leading Australian network operator wanted to gain more insights into its distribution network. These insights include condition monitoring of the medium voltage power cable, identification of hotspots and bottlenecks, and minimizing risks and costs for maintenance and in emergency situations. Therefore, AP Sensing’s Distributed Temperature Sensing (DTS) solution was selected in order for the customer to maximize its assets and take advantage of the related operational cost savings with a noticeable improvement in the network’s efficiency. The operator has four underground power cables (33 kV), with a power circuit length of 20 km. With an eye toward future growth, the operator decided on a six-channel model of AP Sensing’s DTS technology, keeping two channels in reserve.

RTTR

AP Sensing’s solution exceeded all of the client’s requirements. The DTS continuously measures the real-time temperature at the sheath or jacket of the cable. This data, combined with the cable’s load, is continuously fed into a real time thermal rating (RTTR) or dynamic cable rating (DCR) engine and individually modeled per thermal section (in this case, with 11 different laying conditions). This provides both steady-state and transient thermal analysis. Furthermore, conductor temperature is estimated via the measured fiber temperature, together with the current. Continuous temperature monitoring enables the operators to compare the current load with the maximum permissible load (ampacity). Analyzing the original ampacity calculation made during the planning stage with the RTTR results, the operator was able to adjust his steady state load table by +14%. Additionally, it shows that load could be increased by 32% if a temperature of 90 °C is tolerated for 24 hours. If a temperature of 105 °C is tolerated for 24 hours during peak loads or emergencies, a 48% capacity increase can be realized. When overloads need to be applied, RTTR can predict the cable temperature at the end of the emergency period. Alternatively, it can estimate the maximum time the cable can handle an overload before exceeding its recommended maximum. This information is valuable for planning maintenance cases and to better control peak or emergency situations.

SmartVision

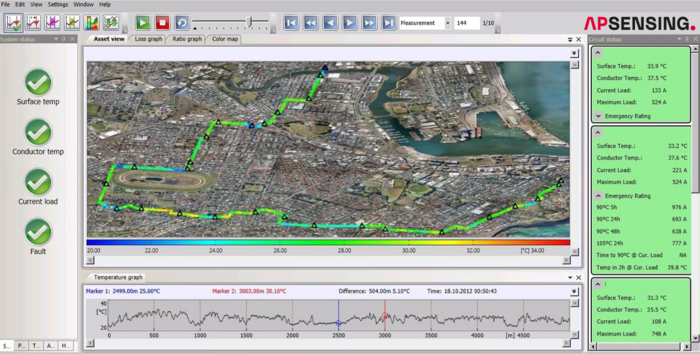

For optimized usability, AP Sensing’s SmartVision software suite provides data acquisition and analysis, data management and asset visualization at a glance. The customer can view and store the analysis, statistics, history trace generation, colored 2D temperature mapping, and further information. It is easily integrated into the operator’s existing client network via SCADA. The operators gain insight along the entire installation by mapping GPS data together with the SmartVision asset viewer software. As shown in the screenshot below, even slight temperature changes can easily be seen when, for example, the sensor cable runs below a warm asphalt street (yellow) or it runs below a rowof trees (blue).

Benefits

AP Sensing’s DTS solution enables the customer to increase utilization by 32%, and in peak load or emergency situations by 48%, without risk to his valuable network assets. After installation and commissioning, the operator was pleased that the new solution exceeded expectations. In particular, the combination of spatial and temperature accuracy mapped along the route of the installation provided a new level of insight into the network’s status.