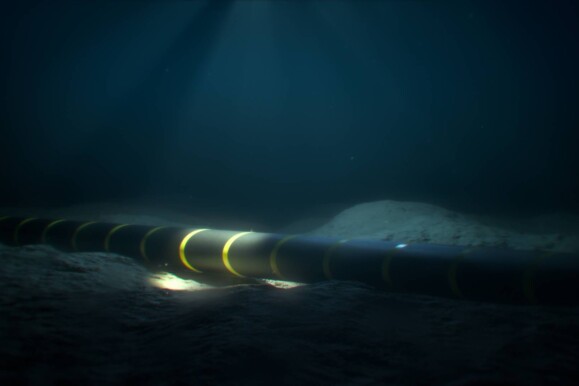

With the launch of its 5th Generation of Distributed Acoustic Sensing (DAS), AP Sensing makes strides in asset monitoring technology with a system that, unlike traditional point sensors, provides gapless monitoring of valuable infrastructures such as pipelines, power cables, and railways.

The future of technology is here: standard fiber optic cables used as continuous sensors for asset protection and monitoring. AP Sensing’s 5th Generation DAS, specifically, utilizes acoustic vibrations along the fiber optic cable in order to detect and precisely locate events in real time such as pipeline leaks, high voltage power cable faults, third party intrusion (TPI) activities, or other abnormal events. Previous versions of this product boasted leading measurement capabilities, but the 5th Generation is also built for rapid adaptation to the asset environment, operation in harsh conditions and installation in remote environments. The 5th Generation DAS utilizes unique detection algorithms to identify and locate critical events with improved detection sensitivity and reliability.

“Our R&D teams in both the UK and Germany spent years tirelessly developing our DAS technology and software, The resulting product we have today shows a mature technology that can really be used to make a difference in protecting people and critical infrastructure everywhere.”

Get an Inside Look at AP Sensing's DAS N51/N52-Series

Fiber optic LHD technology uses a fiber optic sensor cable to measure the temperature at every point along the entire cable, detecting changes in temperature and hotspots along an entire asset. For example, for 10 km of cable, the system measures 10,000 temperature points every 5 seconds. This technology detects hotspots and fires, alarming quickly and providing precise information on fire location, size and spread. It is used in a wide range of applications including traffic and utility tunnels, car parks, conveyors, cable trays, solar farms and battery storage.