Project Overview

Réseau de Transport d’Électricité (RTE) is the electricity transmission system operator of France, responsible for operation, maintenance and development of the French high voltage transmission system. RTE’s recent Intelligent Electricity Network Deployment plan, established from 2017-2020, groups together the most promising and deployable solutions of SmartGrids in order to mitigate the challenges of the energy transition, in which the country intends to be carbon neutral by 2050.

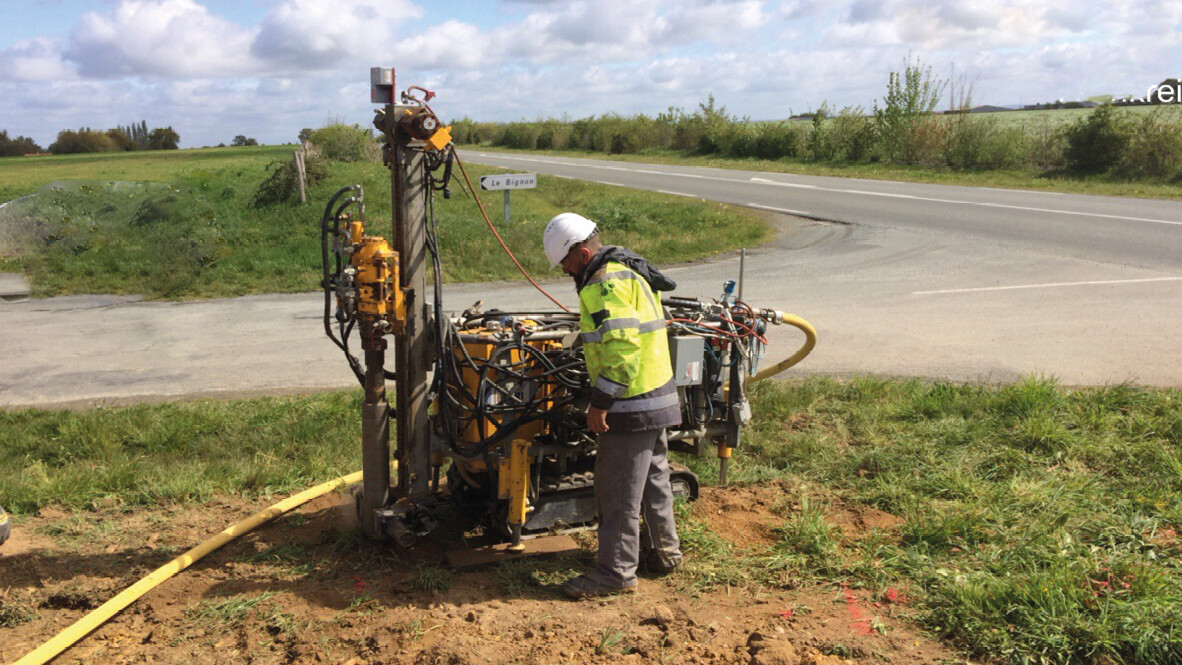

AP Sensing’s technology was deployed by RTE to monitor a 225 kV underground power cable link located in the west of France. The link is approximately 39 km long and monitored for third party intrusion (TPI) activities plus cable faults using our Distributed Acoustic Sensing (DAS) system, as well as hotspots using our Distributed Temperature Sensing (DTS) system. The power link installation is surrounded by frequent agricultural activities that pose no harm to the cable. To mitigate the risk of increased false alarms from these activities, similar events were simulated to test the system based on soil mixing and harvesting agricultural machines.

Solution

The monitoring solution consists of a one-channel N5200A DAS system with a measuring range of 50 km, and a one-channel N4525A DTS instrument, also with a measuring range of 50 km. Both systems are connected to a single mode fiber each within the fiber optic sensing cable, which is installed in a duct approximately 40 mm from two of the three phases, installed in a trefoil configuration. All instruments are mounted in a standard 19” cabinet installed in Merlatière Substation.

System Capabilities

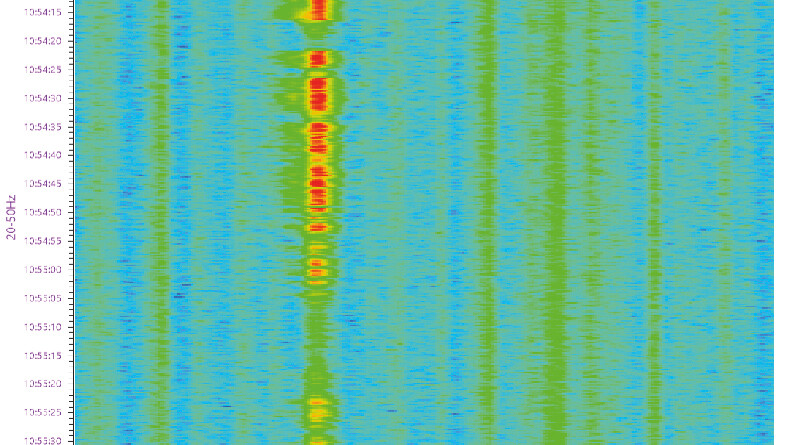

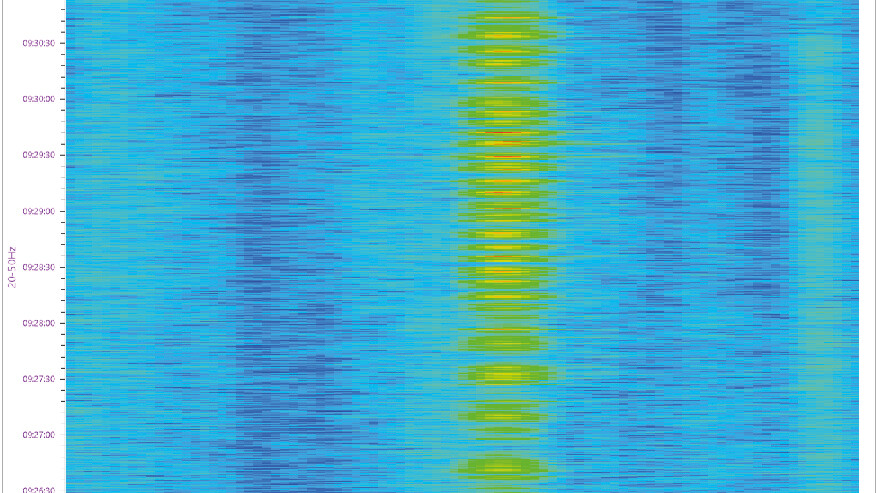

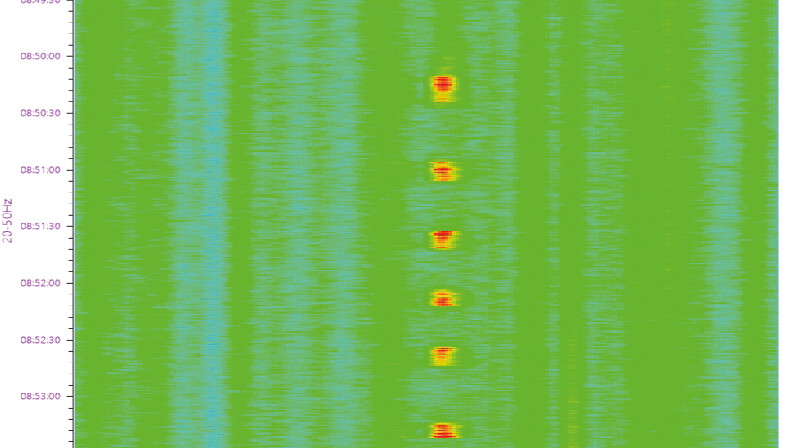

The cable fault and TPI event detection in this project utilizes our DAS measurement technology. The DAS system is configured to monitor the power link in real time, visualize the acoustic energy over time/distance in waterfall plots, store the measured data internally, and trigger an alarm in case of the identification of a risk. Several field tests, such as machinery digging and drilling, were conducted at different locations along the link to simulate real, potential threats. Meanwhile, the DTS system conducts hotspot detection by measuring the ambient temperature of the fiber optic cable and raising an alarm if the ambient temperature changes drastically within a certain period of time. Hotspots, TPI events, cable faults, and fiber break alarms are exported automatically to local csv files. These are parsed, and the alarm details are imported through the customer’s network.

Detection Principles

The detection principle used in this project is based on two types of detection: classic detection and timespace gradient detection. In classic detection, the maximum temperature threshold and maximum temperature difference to the average zone temperature are used for hotspot detection. This is easily configured, but there are several limitations for small hotspots. Time-space gradient detection or “smart monitoring” requires an analysis of the temperature history and an analysis of the ambient temperature for each position. The results are then combined mathematically to determine a measure of unusual behavior, and an alarm is triggered when a certain threshold is exceeded. With time-space gradient detection, a higher sensitivity is achieved than with classic detection, so that much smaller changes in temperature can be detected. To determine the alarm threshold, the data is recorded and analyzed over several weeks.

Project Comissioning

The commissioning procedure was conducted by mapping the sensing fibers to the asset, then by calibrating the temperature traces and acoustic profiles. In addition to the field tests conducted, the DTS and DAS data was collected over several weeks to determine the impact of the background noise and tune the alarm parameters. As most of the manholes were not accessible, and the fiber-to-asset mapping was challenging due to the unknown overlength of the cable loops, both DTS measurements and additional DAS tests helped to identify the overlength accurately.

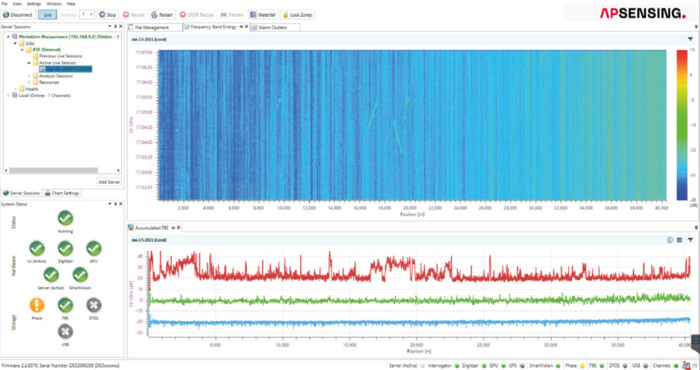

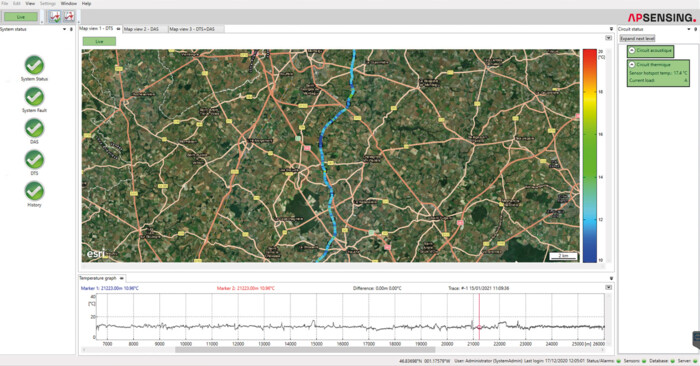

SmartVision

AP Sensing’s SmartVision monitoring software is installed on the main server, which is mounted in the DTS/DAS cabinet. A MapView was implemented for this project in order to visualize the power link, corresponding temperature profiles, and any DTS/DAS alarms in a single map based on the GPS coordinates of the power link. MapView makes the location of any identified threats as simple as possible for the customer. AP Sensing conducted an online training for RTE personnel, followed by an on-site session. The customer was very satisfied with the project deliverables and training.