Project Overview

With the actual accelerated transition towards more sustainable energies, the deployment of wind farms and submarine power cables has significantly increased the last few years and will expand further in the near future. Therefore, monitoring of the growing number of offshore power cables has become very important to identify possible damage risks and avoid long power outages at an early stage. The Distributed Temperature Sensing (DTS) technology is known to offer several advantages for the highvoltage cable applications. It can be used for long-range temperature monitoring, hotspot identification, cable fault localization, real time thermal rating (RTTR), among others.

Especially for submarine power cables, the determination of the burial conditions can play a big role in reducing the risk of cable faults, and which can also be realized based on the DTS technique. In fact, these cables are commonly buried during the installation phase, but may suffer from exposure due to waves and seabed currents. The exposed offshore cable sections may then represent a threat due to possible damage by fishing and anchoring activities which generates costly repairs and power outage, in addition to unforeseen influences on the sensitive marine environment. In fact, there are policies in some countries, e.g. Germany, that regulate the burial depth of power cable systems and therefore the maximum induced temperature increase at the seabed surface in order to avoid any negative impacts of cable warming on the marine environment. By analyzing the load data of the power cable and the temperature traces collected by the DTS system, such exposed sections can be localized, and possible additional protection can be planned precisely in order to perform better predictive maintenance.

Solution

AP Sensing’s approach to determine the exposed submarine locations is based only on the measured power cable load and the temperature traces collected by the DTS instrument. We call this method the Depth of Burial State (DoBS). In contrast to the known Depth of Burial (DoB) technique, our method does not require any precise knowledge of the ambient conditions and thermal parameters of the seabed and does not depend on the absolute temperature values measured along the cable. This significantly reduces the commissioning effort, avoids any uncertainties caused by measurement deviations, and is especially applicable to retrofits, where soil sample data might be outdated or not available at all. The main principle of our method relies on the calculation of the local load temperaturechange correlation function, denoted thereafter as the thermal response. The less the cable is buried, the faster the dissipated heat can be transported away, and hence the lower the temperature change is measured by the fiber upon a load change.

Results

In this case study, we demonstrate the effectiveness of our method by comparing the calculated DoBS results with the exposed locations determined during a Remotely Operated Vehicle (ROV) survey on the 500 kV Skagerrak4 HVDC interconnector between Norway and Denmark, conducted in August 2022. Based on our DoBS solution, we were able to correctly determine all exposed cable positions, in addition to locations with shallow exposures and ducted cable sections in a surveyed offshore length of approximately 22 km.

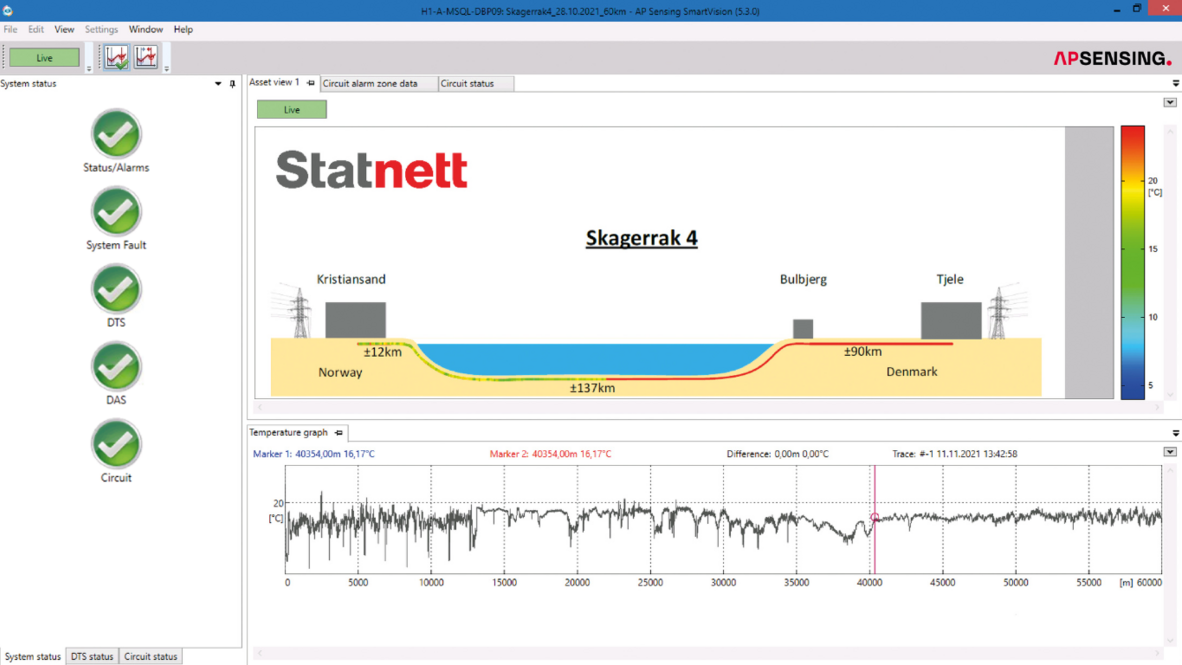

Skagerrak4 is a joint project between two transmission system operators: Statnett in Norway and Energinet in Denmark. The interconnector facilitates more renewable energy production in both countries and ensures an increased security of power supply. Skagerrak4 has a capacity of 700 MW and comprehends a 137 km offshore cable and a 12 km onshore cable in Norway.

For this project, AP Sensing has provided an N45-Series DTS instrument with a range of 60 km for temperature monitoring, hotspot detection, and DoBS calculation in addition to an N52-Series Distributed Acoustic Sensing (DAS) system with a range of 80 km for cable fault localization. Moreover, the Distributed Temperature Leading the Way with Passion. Gradient Sensing (DTGS) measurement data provided by the DAS system are combined with the temperature traces provided by the DTS at long distances in order to significantly enhance the temperature resolution.

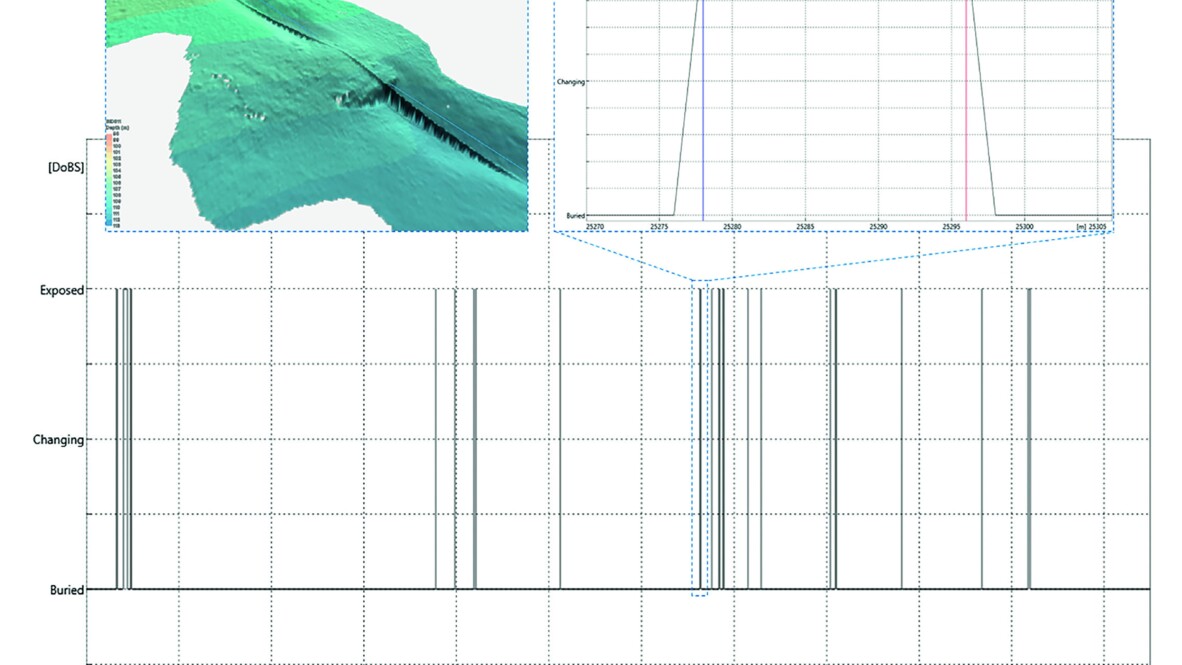

We call this method, the enhanced DTS (eDTS) technique. Both measurement instruments are installed in a rack cabinet in Norway and are connected to a Fiber Optic Cable (FOC), which is bundled to the power cable. Figure 1 shows the asset view in AP Sensing’s operator interface SmartVision, including the temperature profile of the circuit up to 60 km. The temperature profiles are collected every 30 min, and an updated DoBS profile is generated every 12 h. Figure 2 illustrates the calculated DoBS results of the first 22 km offshore segment, starting from the Norwegian side. Commissioning of the DoBS engine was achieved within one day without any additional information of the power cable parameters and seabed properties, and the first results were obtained within approximately one month after system configuration. This shows a clear advantage in comparison to time consuming thermal model generation of other DoB solutions, where configuration can take up to one month, and first calculations may be obtained after several months.

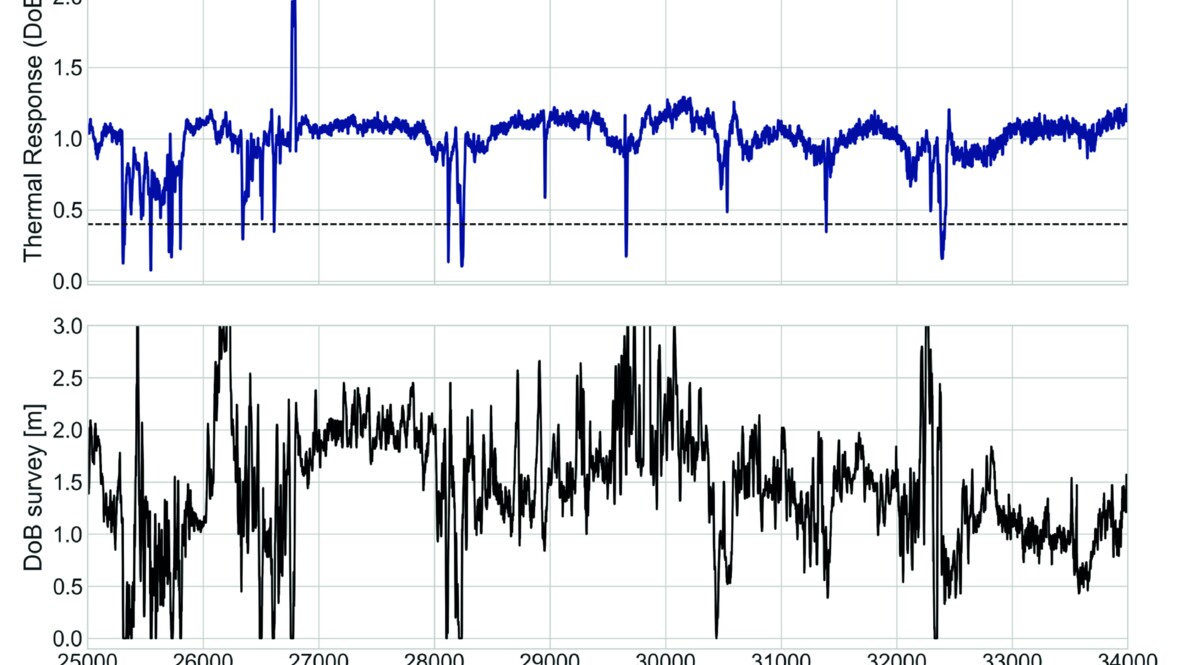

It can be seen in the graph that most of this submarine cable section is buried, whereas some locationsexhibit exposure probably due to the seabed activities, especially at the inshore section. In order to verify the exposure results, an ROV survey was conducted in summer 2022 starting from deep towards shallow water. The ROV was equipped with a video camera and a multibeam scanner, allowing to compare all calculated exposure locations with the actual burial state of the cable. Based on the survey, we were able to determine all exposed cable positions, in addition to locations with shallow exposures and ducted cable sections. An excerpt of the calculated thermal response by the DoBS and the corresponding measured burial depth by the ROV multibeam scanner are shown in Figure 3. The thermal response is scaled so that a value of 1 reflects typical burial conditions, while low values <0.4 indicate a cable exposure, which is also validated by the survey, and values in between reveal shallow exposure.

There exist a few locations where the thermal response drops below the threshold of 0.4, but the survey does not indicate an exposure. For all these locations it is confirmed, by inspection of the corresponding ROV videos, that the cable is covered by rocks or gravel. Therefore, the heat transport is dominated by convection here, and no temperature based method can distinguish these locations from true exposures. However, these findings might be of interest to the cable operator since the results can serve as a permanent real-time validation of the DoBS system if the locations are known. In case the locations are not known, they might be considered as additional points of interest that deserve further inspection.

It can also be seen in the figure that there are locations with a higher thermal response of ~2. These locations denote a high thermal confinement, indicating a cable installation in a duct or other kind of Cable Protection Systems (CPS). This burial state cannot be identifiedby the multibeam scanner, which shows the strength of the DoBS engine. The ducted locations were also confirmed by Statnett based on their internal documentation.

Conclusion

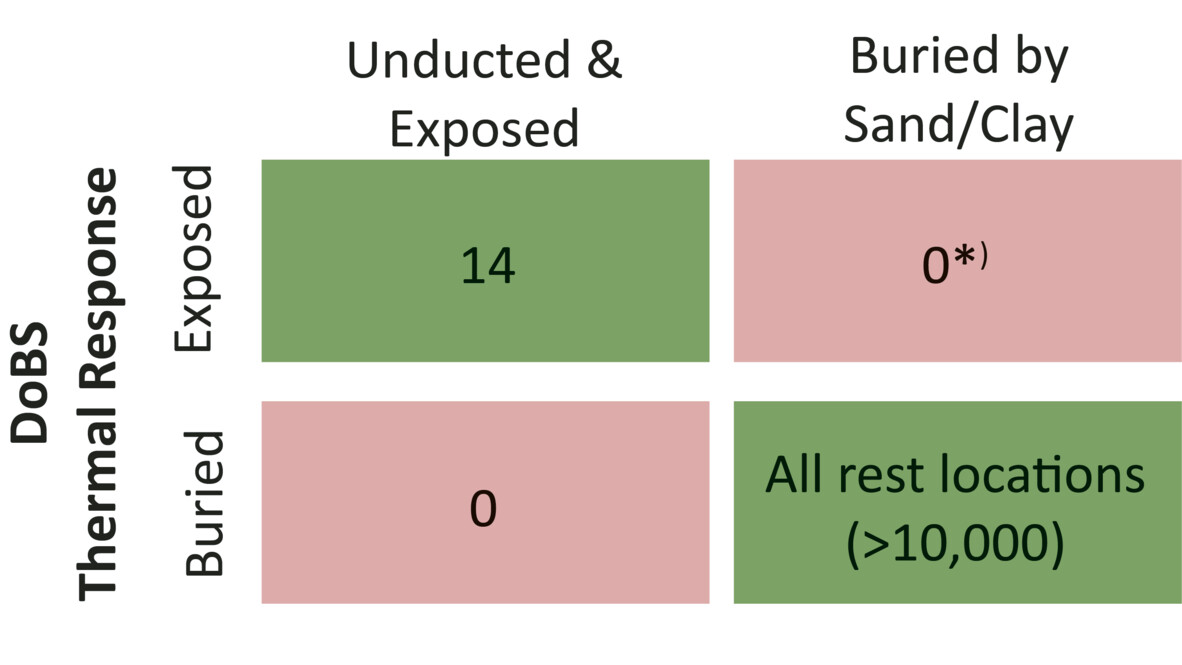

We have implemented a fast and accurate approach to calculate the depth of burial state of submarine power cables based solely on the load data and temperature traces. The effectiveness of this method is demonstrated by comparing the calculated DoBS results with the exposed locations determined during an ROV survey on the Skagerrak4 HVDC interconnector between Norway and Denmark. All exposed areas, incl. shallow exposures and ducted sections, have been successfully identified by the DoBS signal as shown in the following matrix. Along the entire surveyed offshore length of 22 km, the DoBS signal indicated no false negatives and clearly identified five areas which are covered by rock berms and gravel where heat transfer is dominated by convection.