Project Overview

The scope of the Taif-Turubah-Ranyah-AlKhurmah (TTRA) Water Transmission System (WTS) in Saudi Arabia is to transport potable water produced at Shoaiba desalination plant from the new strategic reservoir at Taif up to Abu Raka and further on to Baha. Furthermore, several villages along the route are supplied with potable water. The new 40” pipeline section between Taif and Abu Raka has been interconnected with the existing pipeline up to Baha and form one combined system with an approximate total length of 210 km. The pipelines of the TTRA WTS are routed in areas with considerable construction activities. In order to detect any potentially harmful third party intrusion (TPI) activities in the vicinity of the buried pipelines, the owner requested the deployment of a fiber opticbased Distributed Acoustic Sensing (DAS) system so that the maintenance and security teams can be enabled to stop these activities, if necessary, before the pipelines and fiber optic cables can be damaged. In addition to TPI event detection, the DAS systems are configured to detect pipeline leaks and related leak locations.

Solution

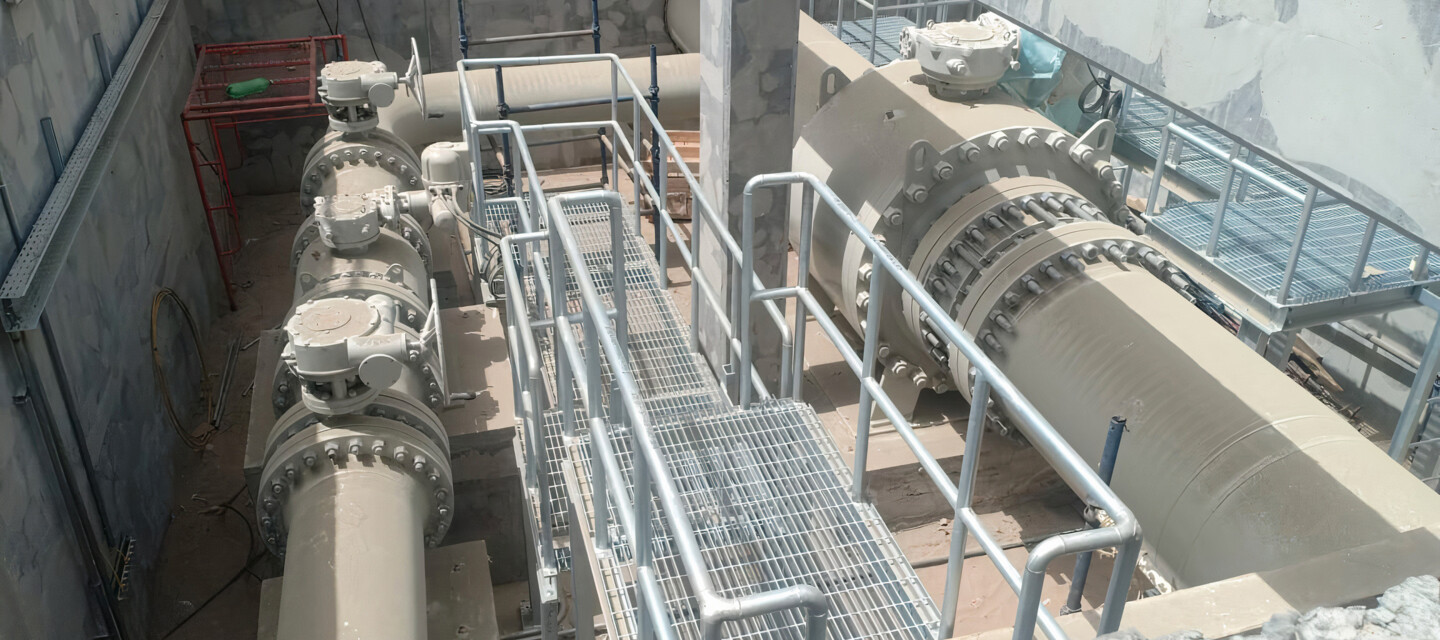

AP Sensing’s DAS solution has been selected to monitor the entire length of the pipeline system. The monitoring solution consists of six single-channel N5200A DAS instruments with measuring ranges of 50 km and 70 km. Each of the systems is connected to a single-mode fiber within a non-metallic 72-fibers cable laid along the pipeline. The fiber optic cable is installed in a duct and placed at the 2 o’clock position within a distance of 15 cm to 30 cm from the pipeline wall. All sensing instruments are mounted in standard 19” cabinets located in four substations along the pipeline system, and two separate servers with the main operator interface SmartVision are configured to visualize and send the alarm information to SCADA for each of the existing and new pipeline sections. Additionally, two workstations are available in the control center to provide a quick insight into the monitoring system to the operator. The DAS solution is configured to monitor the entire pipeline system in real time, visualize the acoustic energy over time/distance in waterfall plots, store the measured data on external storage units, and trigger an alarm in the event of a risk. Alarm notifications include information on the type, time, and location of the threat. While detection of TPI events relies on identification of large-magnitude, low-frequency vibrations generated in the ground, the classifier of leak events rests on capturing high-frequency signals in combination with a temperature change that can be measured by the inherent Distributed Temperature Gradient Sensing (DTGS) technique.

Results

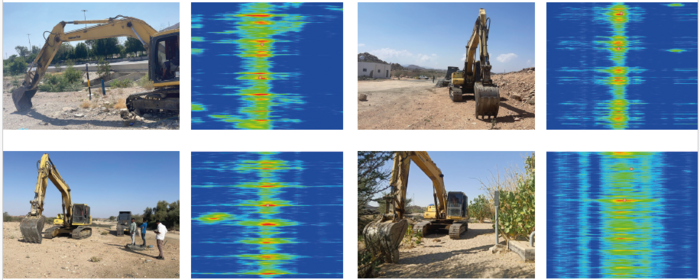

In order to simulate real potential threats and to configure the alarm parameters properly, machinery digging tests were conducted at twelve different locations along the entire pipeline route, especially since various ground types exist in that region. Depending on the soil type and distance to the fiber optic cable, the acoustic waves generated by digging activity may produce different signal imprints with different magnitude and width values (see Figure 1). AP Sensing’s event classifier algorithms are concepted to recognize a variety of different digging activities and trigger an alarm with a high confidence level while keeping a low false alarm rate (FAR).

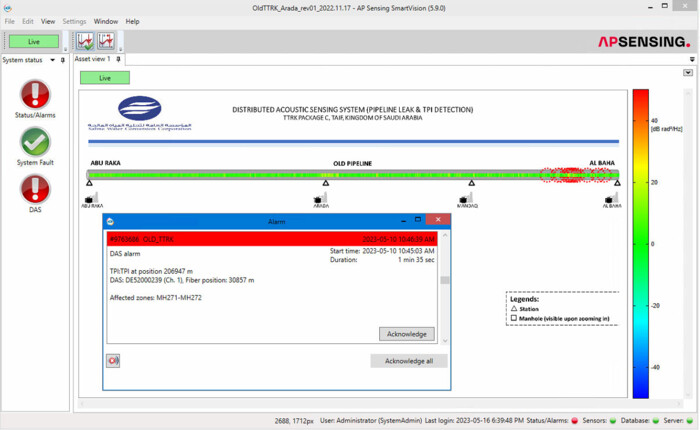

The alarm notification is visualized on AP Sensing’s monitoring platform SmartVision (see Figure 2) and forwarded to the SCADA system of the pipeline owner via Modbus TCP/IP. Additionally, the frequency band energy (FBE) data is streamed to the asset viewer in SmartVision to allow the operator to have an instantaneous representation of the acoustic energy mapped correctly on top of the pipeline. In the event of a TPI or leak events, the operator is able to click on the alarm location in SmartVision and listen to the acoustic signals which are streamed directly from the corresponding DAS system.

Conclusion

The implementation of AP Sensing’s DAS monitoring systems has proven to be an efficient solution for TPI events detection and location. In fact, since commissioning of the solution, several real activities near the pipeline such as trenching, jackhammering, asphalt breaking, and road construction activities have been correctly detected and verified. The alarms have been reported accordingly to the operators via SmartVision to the SCADA system.