Project Overview

The operators of a 72 km CO₂ pipeline required a reliable, fast, and accurate system for leak detection and third party intrusion (TPI) monitoring to safeguard their critical infrastructure. Transporting CO₂ under high pressure (278 bar) through an eight-inch pipeline at a flow rate of 16 MMSCFD (one million standard cubic feet per day), the system needed to ensure operational safety and efficiency. AP Sensing delivered a state-of-the-art solution, combining acoustic and temperature sensing using dedicated fibers within a telecom cable.

Solution

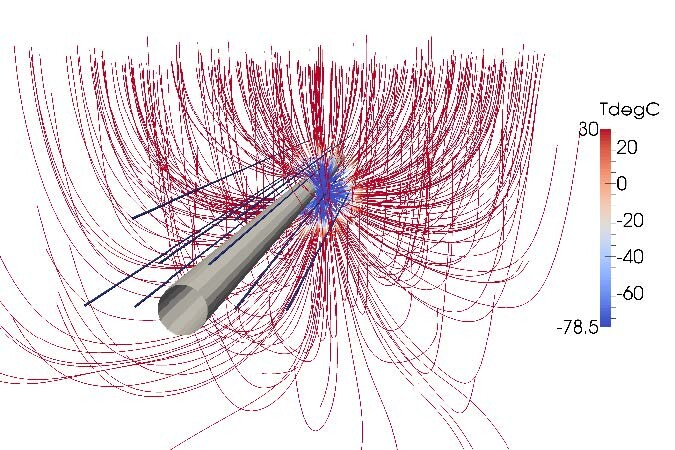

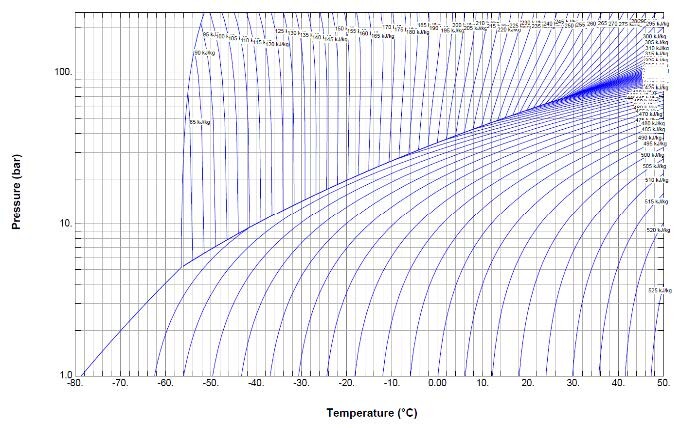

Three DTS interrogators were installed along the pipeline to monitor temperature changes. In the event of a leak, the rapid cooling caused by phase change and the Joule-Thomson effect is detected, triggering an immediate alarm. This thermal-based method delivers a high probability of detection (POD) and minimizes nuisance alarm rates (NAR).

The fiber optic cable, double-sheathed and steel-armored, serves as a backbone for leakage detection, TPI monitoring, and Ethernet/SDH communication.

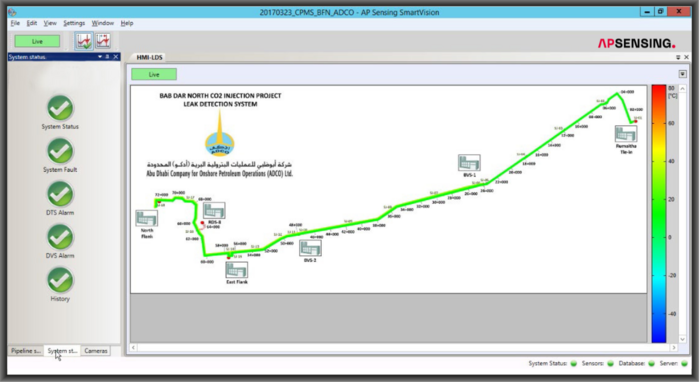

SmartVision

SmartVision serves as the central hub for monitoring data, integrating real-time information from all devices and making it accessible to multiple users across various locations. Operators stay informed of alarm conditions through a clear and intuitive graphical user interface (GUI), enabling swift and effective decision-making.

The main server for the leak detection system is located at the remote de-gassing station, where SmartVision manages all temperature and vibration alarms. With its TCP/IP-based client architecture, SmartVision seamlessly interfaces with the SCADA/DCS platform, providing comprehensive system and alarm status updates.

AP Sensing’s solution integrates acoustic sensing and temperature sensing technologies into a single platform, ensuring the reliable transportation of CO₂ to the BAB Far North Flanks while maintaining safety and efficiency.

Conclusion

AP Sensing‘s comprehensive solution has enhanced the operational safety and reliability of the 72 km CO₂ pipeline. By leveraging DTS and DVS technologies integrated into a unified SmartVision platform, operators have a complete view of the pipeline conditions. The project’s success was bolstered by AP Sensing’s experienced Project Management and Engineering team, who ensured smooth installation, commissioning, and cable splicing. The solution provides robust protection against leaks and interference, ensuring safe and uninterrupted CO₂ transport.