Project Overview

AP Sensing was selected to provide tension ring and tank wall monitoring for maximum asset protection by GPS Chemoil. GPS Chemoil is a leading oil storage company. It owns and operates two state-of-the-art oil storage terminals in Fujairah. The expansion of the GPS Chemoil facility in Fujairah increases the number of tanks at the terminal to 24, ranging in sizes from 9 m to 52 m in diameter. These tanks are used for liquid petroleum storage, such as fuel oil, jet oil and diesel. All 24 tanks are monitored with one 8 km Distributed Temperature Sensing (DTS) system, with a second DTS system used to monitor the pump house.

The tank farm now has all the advantages of a fiber optic-based DTS system including a passive sensor cable that is impervious to difficult environmental conditions and electromagnetic interference (EMI), and is certified for ATEX down to zone 0. In contrast to point sensors, it is also possible to use a single device to monitor multiple tanks. Fewer control systems means better reliability; with AP Sensing’s outstanding reliability record and support from regional partner Tyco Fire and Security, the client decided to use only one device instead of two for a dual redundant architecture.

Solution

The fiber optic cable is mounted around the tension ring at the top and also secured to the side of the tank. The AP Sensing sensor cable is able to withstand temperatures beyond 750 °C for over two hours according to IEC 60331-25. This gives the client the ability to not only detect a fire, but also monitor its effect on the tank by looking at the tank wall temperature from base to roof. This vital piece of information gives emergency responders the benefit of knowing if the tank wall is nearing failure temperature or if the tank deluge systems are cooling the walls as they should.

SmartVision

AP Sensing’s SmartVision software gives the client real time information on the temperatures around each and every tank while looking at one screen. The software maps temperature information to the tank layout. In addition, Modbus interface provides the site control system with the same information for process control solutions and triggers an alarm in the event of a fire. The operator is immediately informed and is able to take appropriate countermeasures.

Design Recommendation

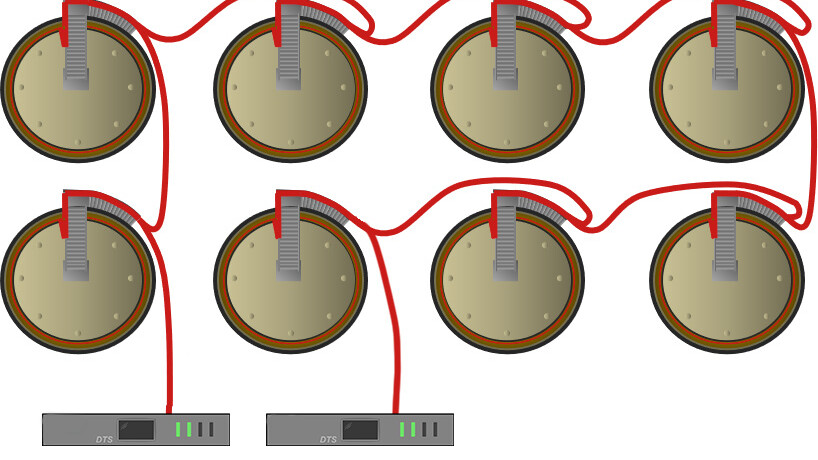

To reach the maximum level of availability, a fully redundant setup can be realized in a cost-effective manner. For this, a second DTS can be added which monitors the deployed cable independently from the other DTS. Using a fully-redundant setup with two systems adds no additional employment costs. As shown in the diagram above, both fibers inside a single cable can be utilized.

Both DTS instruments permanently monitor the entire sensor cable length and work independently, thereby achieving full redundancy throughout the entire tank farm. Oil terminal monitoring and tank fire detection have come a long way from simple stand-alone pneumatic designs. With AP Sensing it continues to advance, giving tank farm operators more and more vital information that can save lives and protect their valuable assets.