Project Overview

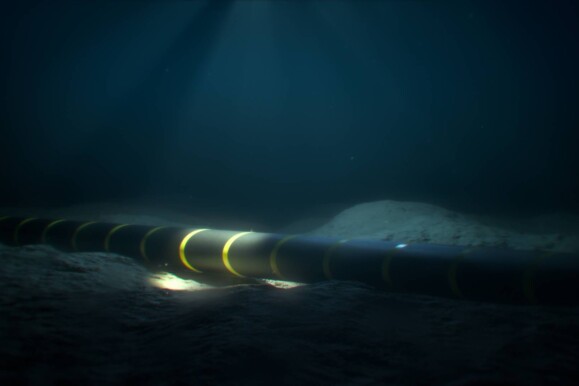

The National Grid Corporation of the Philippines (NCGP) required a reliable monitoring solution for their high-voltage (230kV) subsea power cable, which supplies power to connect the islands of Cebu, Negros, and Panay. The cable extends approximately 30 km, consisting of three sections:

- AP Sensing’s a land cable section on the Negros side (approximately 60 m)

- a subsea section (about 28 km)

- a land cable section on the Cebu side (about 60 m)

Monitoring subsea power cables is crucial for ensuring the reliability and longevity of critical energy infrastructure. Subsea cables are exposed to harsh environmental conditions, including temperature fluctuations, water pressure, and potential physical damage from anchors or marine activities. By implementing a robust monitoring solution, operators can detect issues early, prevent costly outages, and optimize the cable‘s operational performance, ensuring continuous power delivery across vast distances. For energy providers, monitoring these cables means minimizing downtime, extending asset life, and ensuring maximum operational efficiency.

Solution

The operators selected AP Sensing’s Long-Range / Single mode Distributed Temperature Sensing (DTS) solution with a 50 km measurement range and six channels. This longer range and the additional six channels were configured for the existing two circuits with 6 phases. The DTS unit is located in the Calatrava Substation Control Room. The DTS measurements are transmitted via a single-mode fiber to the onshore NCGP infrastructure.

The AP Sensing software, including SmartVision and Real-Time Thermal Rating (RTTR), is installed on an industrial server located at the rack, enabling access and local operation. The circuit load is simulated using Modbus Poll Software, and alarm values and hotspot temperature data are transmitted via the Modbus TCP interface. Modbus TCP is a communication protocol that allows devices to exchange data over Ethernet, ensuring efficient and reliable real-time monitoring and control. AP Sensing‘s SmartVision software suite integrates monitoring data from multiple sources, performs intelligent analysis, stores it in a central database, and provides schematic asset visualization. Additionally, the RTTR software continuously calculates the conductor temperature and predicts the maximum permissible load for steady-state and emergency situations, following industry standards IEC 60287 and IEC 60853.

Benefits

The solution provides comprehensive monitoring across all three sections of the cable, including both land and subsea segments, to ensure optimal performance. Safety is enhanced through the RTTR software, which supports network operation at the highest safe ampacity levels by accurately predicting conductor temperatures and determining the maximum permissible load. The SmartVision software enables advanced data integration, seamlessly combining information from various sources for intelligent analysis and visualization, which supports better decision-making. Additionally, the 50-kilometer measurement range and six-channel configuration are essential for effective monitoring of the project’s existing infrastructure. To support smooth operation, operators received training on the software, alarm features, and overall system functionality, ensuring they are well-prepared to manage the monitoring solution.

Conclusion

AP Sensing was selected for this critical infrastructure project, delivering a robust, reliable, and innovative monitoring solution for the National Grid Corporation of the Philippines‘ subsea power cable. Our SmartVision and RTTR technologies provided NGCP with real-time monitoring and advanced data analytics, ensuring continuous performance and safety under challenging environmental conditions. By choosing AP Sensing, the NGCP is able to safeguard its valuable assets while optimizing operational efficiency.