Project Overview

Solar energy is growing in popularity and importance worldwide as a clean and renewable source of energy that is also becoming increasingly affordable and accessible. However, solar panels, defective cables, and plugs that overheat or catch fire pose serious risks to industrial sites and buildings.

Overheating can cause damage to the panels themselves, leading to reduced efficiency and even complete failure. In extreme cases, overheating may also lead to electrical fires that spread to nearby buildings or equipment. This is especially dangerous in data centers where sensitive electronic equipment and critical data are stored, as a fire could cause irreparable damage and result in significant financial losses for the data centers and their customers. Furthermore, a rooftop fire is a serious challenge for intervention forces such as the fire brigade, as smoke from a rooftop fire can be sucked into the air inlet of an HVAC system and distributed throughout the building, triggering smoke detectors in various locations and requiring evacuation of the building and a time-consuming search for the original source of the fire. In the meantime, the fire on the roof has time to develop.

In 2021 a major tech company began looking for a fire detection and monitoring solution, specifically for continuously monitoring its rooftop solar panels at a new industrial site.

Solution

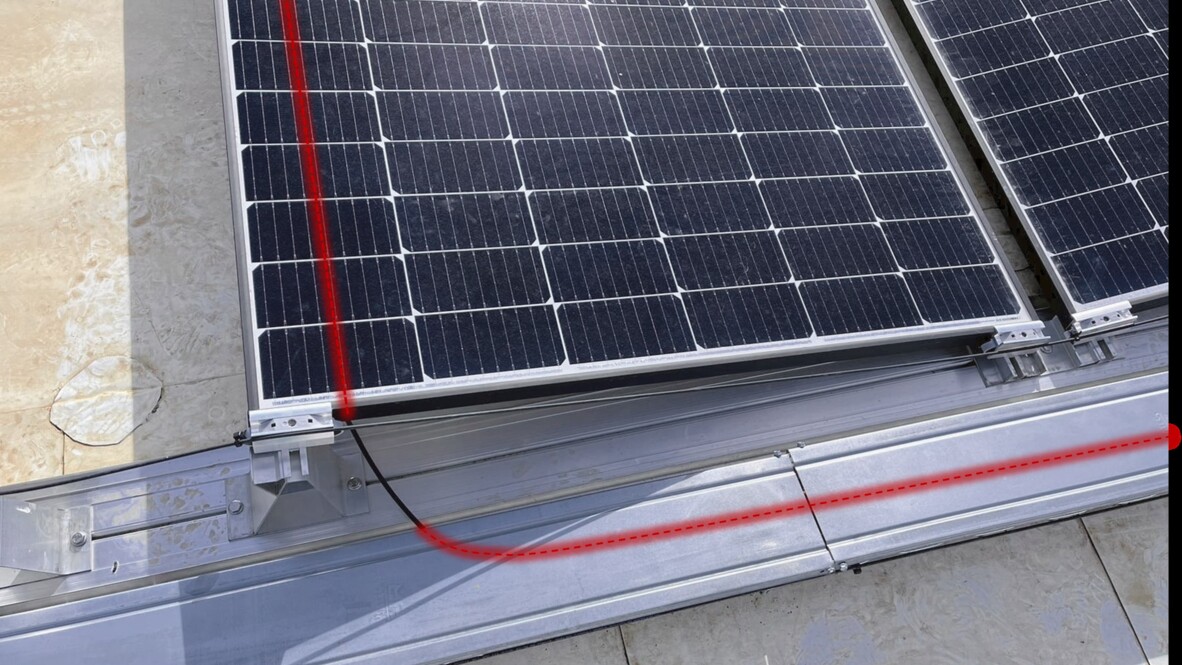

AP Sensing’s local partner TASC provided the customer with one fiber optic Linear Heat Detection (LHD) device with four channels, three monitoring approximately 1 km distances and the fourth approximately 3.6 km, all in a single-ended configuration. The fiber optic cable zigzags between each row of solar panels in order to continuously measure the temperature of both the solar panels and the roof in case a fire were approximately 3.6 km, all in a single-ended configuration. The fiber optic cable zigzags between each row of solar panels in order to continuously measure the temperature of both the solar panels and the roof in case a fire were to develop below the roof or in a cable tray.

Additionally, AP Sensing’s S2000A fiber optic safety cable with a 4 mm diameter provides an extra robust solution, as the cable is low maintenance, certified to withstand at least 750 °C for up to 2 hours, and designed to withstand harsh environmental conditions.

Our LHD solution is integrated into the client’s existing fire control system via relays and TASC also ensured that Modbus TCP/IP is configured so it can be used by the client in the future.

Benefits

Fiber optic LHD is highly effective because it provides continuous, real-time monitoring of temperature changes along the entire length of the cable. Benefits include:

Early Detection of Hotspots

Detecting temperature changes at a very early stage enables precise localization, which helps intervention forces (technicians/the fire brigade) to prevent fires or fire spread.

High Accuracy

Accurate temperature measurements and detection of temperature changes with precise localization.

Rapid Response

When a hotspot or high-temperature event is detected, the system triggers alarms within seconds, allowing for a rapid response to the issue.

Low Maintenance

Does not require regular cleaning or calibration, reducing operational costs.

Overall, fiber optic LHD provides a reliable and efficient means of monitoring solar panels and can help prevent overheating, fires and other potential issues, ultimately improving the safety and performance of solar panel systems.

Conclusion

This installation was commissioned remotely by TASC in December 2022; the customer was satisfied with our cost-effective, continuous solution for real-time monitoring of temperature changes and hotspots, utimately improving the safety and performance of its solar panel systems and overall operations.