Project Overview

In order to ensure the safe, efficient and scientific operation of underground gas storage groups, real-time measurement of injection-production profiles, wellbore integrity detection, pressure field, fluid field, and fluid components monitoring are necessary. AP Sensing, alongside our local partner, recently provided a downhole oil and gas monitoring solution to CNPC Daqing Oilfield in China.

Utilizing Distributed Temperatures Sensing (DTS) and Distributed Acoustic Sensing (DAS) technologies as a fiber pressure gauge, AP Sensing’s solution provides data for management of operations, safety evaluation and dynamic analysis of the gas storage group. The customer sought out a solution to monitor the temperature of four gas storage wells, with instruments that should withstand temperatures down to -10 °C and are installed onsite, which is an ATEX Zone 1 (meaning normal duties are accompanied by the occasional presence of explosive gases or combustible dust).

Solution

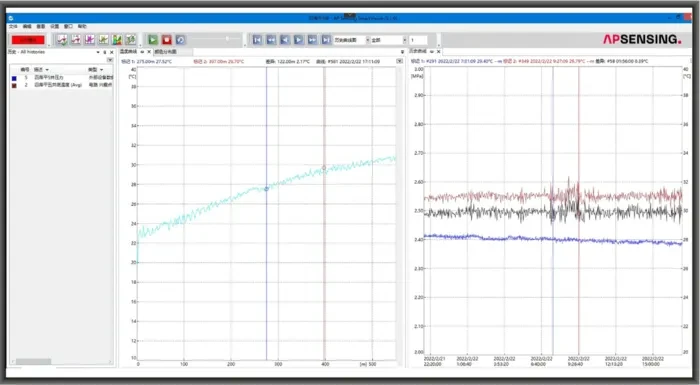

For this project, two DTS N4386B devices were used alongside a downhole fiber optic cable that is permanently installed in the wells. These two devices with ATEX housing are installed at two well sites in order to monitor the four different wells. The ambient temperature onsite ranges from -30 °C to +40 °C. Additionally, AP Sensing’s SmartVision software is utilized for data analysis and the pressure gauge is connected to SmartVision via Modbus TCP. An important project requirement met by AP Sensing was ATEX housing with an intrinsically safer laser.

Project

The wells are vertical wells with casing completion. Through the analysis of acoustic, temperature and pressure data, the production and injection profiles of monitoring wells can be explained, leading to better understanding of the state of the underground gas storage and providing data that supports taking next steps when needed. Simultaneously, the integrity of the wellbore is monitored, and acoustic and temperature monitoring of entire well sections is used to understand the integrity of the completion string such as production tubing and casing. AP Sensing’s DTS plus DAS monitoring solution can be used for verification and interpretation of well status, maximized accuracy of interpretation, improved accuracy of the analysis results of the production and injection profile, and clear recording of abnormal downhole events. These records are more accurate than conventional monitoring methods for obtaining downhole condition insights. Our solution provides complete understanding of gas injection and production, helping the operator to make a complete assessment of all downhole production and respond quickly in emergencies.

Conclusion

Five local operators were trained after project commissioning in China and the client was satisfied with the solution, deciding to execute another upcoming project in Changquing Oilfield in 2022. In the future, the monitoring of gas storage should include geological integrity, wellbore integrity, and ground integrity, and permanent fiber optic monitoring will become the most important technology in this field.