Project Overview

The Mecca Royal Clock Tower (also known as one of the Abraj Al-Bait Towers) is an engineering and architectural marvel and is located near the world’s largest mosque as well as Islam’s most sacred site, the Masjid al-Haram. It contains the tallest hotel, the tallest clock tower, and the largest clock face in the world. In addition to the construction challenges and intricate workings of the huge clock, the tower is illuminated with 21,000 white and green lights, and two million LED lights.

In order to protect this unique infrastructure from overheating or fire damage, AP Sensing’s Linear Heat Detection (LHD) solution was selected as the fire detection technology of choice.

Solution

LHD utilizes a fiber optic sensing cable as a linear heat detector. The system continuously monitors thousands of temperature points along the asset in real time, detecting abnormal heat developments by taking the historical data of seasonal or diurnal temperature changes into account. AP Sensing’s technology has the industry’s lowest false alarm rate, and provides the information needed so the operator can react quickly in case of an emergency.

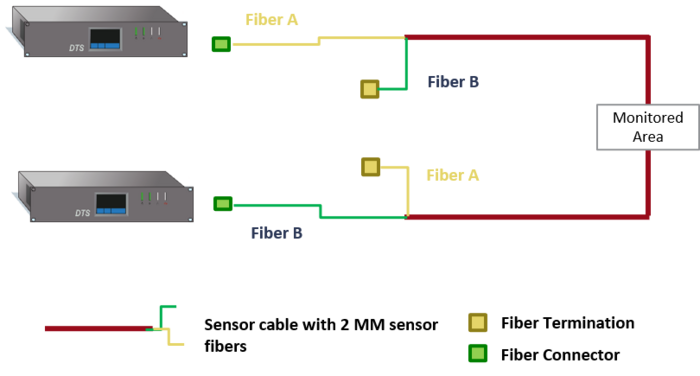

Our LHD system, based on Distributed Temperature Sensing (DTS) technology, is designed for harsh conditions and virtually maintenance-free. For this project, four DTS devices were installed to ensure continuous, fully redundant monitoring in real time.

Design Concept

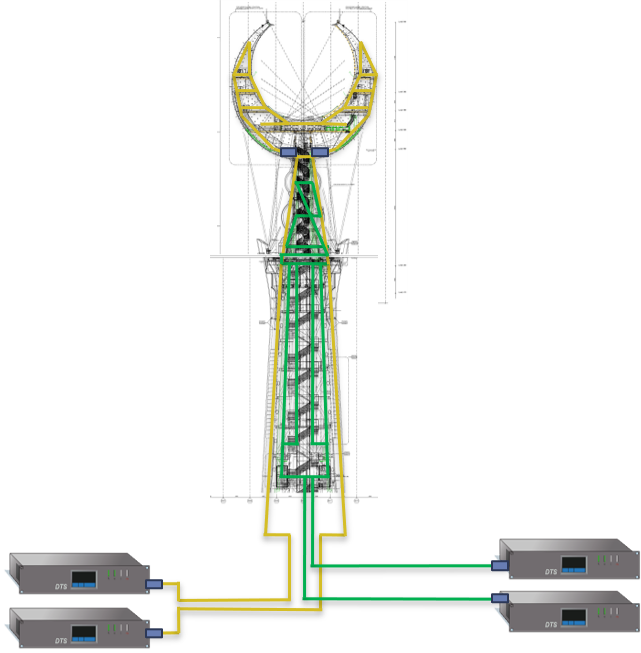

Together with local partners, the decision was made to divide the lower areas into four sections. This ensures an efficient Installation and the highest performance; the system is configured with complete system redundancy, ensuring gapless monitoring even in the unlikely event of a fiber break. The four sensor cables can be divided into 256 zones, each Zone with its own alarm criteria, which was ideal for covering the media panels, platforms and cable trays in each of the four sections. The enormous media walls were installed on each side of the tower below the clock. Two of these measure 70 m x 10 m, and two 40 m x 10 m, and together they contain two million LEDs. The 16 km sensor cable is connected to the heat sink for the LEDs and is then routed throughout the walls in a tight pattern with 50 cm spacing. This ensures that all four walls (which generate 1.8 MW) can be effectively monitored, despite direct sunshine, cool temperatures at night or in the shade, and thermal effects from wind.

Follow-up Project

After years of issue-free operation, the client decided to expand the DTS coverage beyond the media walls to include the crescent itself, as well as the technical rooms and loudspeaker amplifier rooms below. The crescent is 23 m high and weighs some 35 tons, with a complex series of lighting inside. It is made of fiberglass-backed mosaic gold. The massive loudspeakers and their power supply are located in the minaret base and emit calls to Prayer that can be heard 7 km away. Some 21,000 lamps illuminate the

base, which can be seen 30 km away.

Installation

Proven as the most modern and rugged system of heat detection and monitoring available, AP Sensing’s LHD system was selected again for the expansion of the heat detection system. Four LHD devices were installed to ensure continuous, fullyredundant monitoring in real-time. Planning together with local partners, it was decided to install two LHD devices to monitor the spire, amplifier room and the crescent base, and an additional two devices to monitor the flashing lights along the cable in the crescent. The resulting setup is fully redundant: even in the unlikely event of a fiber break, monitoring continues uninterrupted. The ability to configure up to 256 zones per section means that, for example, individual loudspeaker rows, or the rising mains, or the flashing lights in the crescent can each be monitored according to their specific requirements. Each DTS device has 19 configurable potential-free relay contacts (relay #1 is reserved for system faults). Each is equipped with a Modbus TCP interface for temperature and alarm export.

Conclusion

Thanks to the combined efforts of a cross-functional team, the LHD unit is optimally installed, providing a safe and effective deployment. AP Sensing’s unique code-correlated Optical Time Domain Reflectometry (OTDR) technology precisely locates hotspots and alarm conditions in real time – extremely valuable assets remain protected.

Furthermore, the latest AP Sensing LHD Mecca project reduced the overall complexity of the installation and the zone mapping, thanks to the way the units were separated from. This setup also made it possible to use independent systems in the fire control panel areas.