Project Overview

HVAC power cables are vital for power transmission, and monitoring their condition is crucial for ensuring safe operations and promptly addressing defects or faults to minimize downtime. To enhance reliability, Energinet and AP Sensing implemented a pilot installation of AP Sensing’s fiber-based Current Conitoring solution (FbCM) on a new 132 kV HVAC cable connecting two substations in Copenhagen. This cable, installed in a cross-bonding configuration, spans two major sections totaling 3.7 km.

Solution

An AP Sensing’s Distributed Acoustic Sensing (DAS) instrument was installed in one of the substations, offering exceptional asset monitoring capabilities, such as detecting cable faults and third-party intrusions. This DAS system was complemented by AP Sensing’s FbCM solution, which was connected to each bonding lead at all five link boxes (four cross-bonding and one grounding box) and to a telecom fiber running parallel to the power cable. The FbCM is completely passive, requiring no power supply, and is galvanically isolated from the HVAC cable and link boxes. This design ensures that no cable components need to be disconnected for installation, allowing the system to be installed on an operational cable.

The FbCM creates strain on an optical fiber proportional to the current in a bonding lead by using a stretcher element driven by a current transformer. This strain is measured by the DAS and converted back into current, which is then reported as the 50 Hz component to AP Sensing’s SmartVision asset viewer.

Results

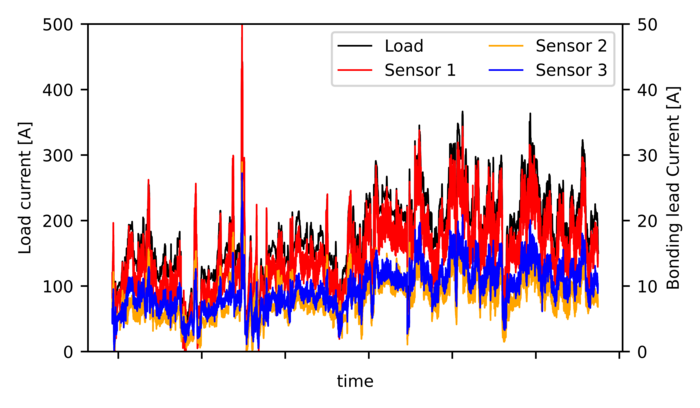

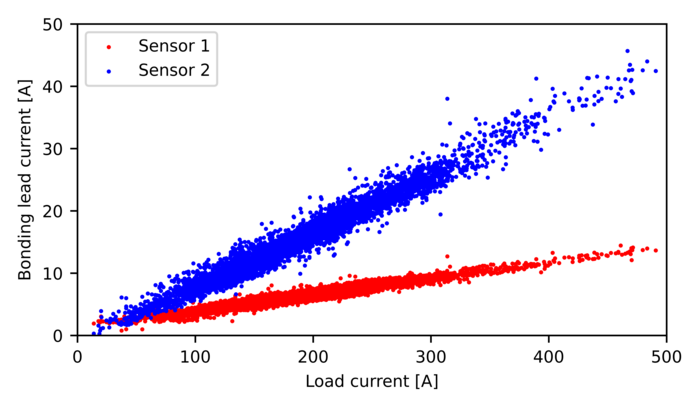

The bonding lead currents were monitored for a full year, providing a comprehensive history across various operating conditions. Our evaluation of the cable performance yielded positive results. Continuous monitoring confirmed stable operation without any observable degradation or season-related effects. Notably, the cable maintained consistent performance even under challenging conditions, including significant power fluctuations and directional changes, confirming a reliable and safe cable installation. Since the sheath currents are induced by the load current, they closely follow the load, showing a strong correlation. Due to length imbalances between minor sections of the HVAC cable, the relationship between bonding lead currents and load currents varies in scale and shift between link boxes and phases.

Additionally, variations in inductance and capacitance between minor sections lead to changes in this relationship. With the measurement history, changes in the correlation can be used as indicators of the cable’s health. Events like link box flooding or ground faults will lead to drastic changes, while the gradual degradation of cable components will show more subtle changes over time. In the event of a fault, measurements from multiple link boxes and all phases can help localize the issue by analyzing which sensors are affected.

Conclusion

AP Sensing’s FbCM solution represents a significant advancement in HVAC cable condition monitoring. It complements existing Distributed Temperature Sensing (DTS) and Distributed Acoustic Sensing (DAS) technologies by extending their reach to a wider range of cable system components. This broader monitoring scope includes critical areas such as link boxes (e.g., link box flooding, SVL defects) and cable degradation itself. By incorporating FbCM, a more holistic understanding of cable health is achieved, empowering proactive maintenance strategies and enhancing system reliability.