Project Overview

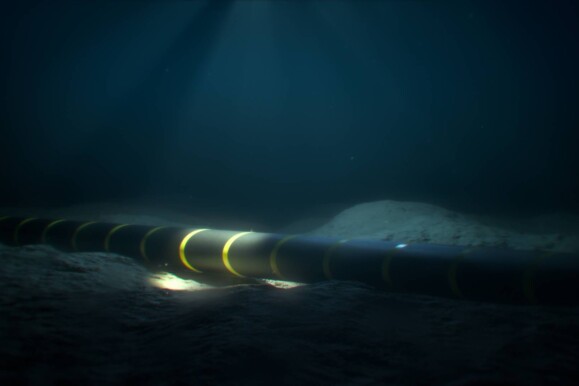

A ±320 kV, 700 MW HVDC submarine interconnector was constructed to link two European countries. Spanning more that 300 kilometers, this advanced infrastructure runs beneath the sea and connects Country A and Country B. As a critical asset in the European transmission grid, the interconnector plays a vital role in integrating renewable energy sources, such as wind power, while enhancing the overall reliability of electricity supply. Recognized as a Project of Common Interest (PCI) by the European Commission, the project received EU funding to support its contribution to developing a sustainable and interconnected energy network across Europe. To ensure the safety and efficiency of the interconnector, the leading European transmission system operator (TSO) required a robust, real-time monitoring solution. AP Sensing’s Distributed Acoustic Sensing (DAS) technology was selected to deliver continuous condition monitoring and rapid fault detection along the cable route. This cutting-edge solution supports uninterrupted power transmission while safeguarding critical infrastructure.

Solution

AP Sensing deployed two Distributed Acoustic Sensing (DAS) instruments to monitor the interconnector, delivering comprehensive and real-time insights into the cable’s condition. At the landfall site in Country B, a DAS system with a range extender was installed in an existing rack, enabling continuous monitoring of 150 kilometers of submarine cable. To achieve accurate measurements over these long distances, a specialized low-loss fiber was utilized. While this fiber involves a higher initial investment, it significantly enhances signal quality and system performance, making it an optimal choice for critical infrastructure. A range extender module was also integrated, extending the monitoring coverage beyond the standard 100-kilometer DAS range to ensure complete oversight of this crucial section. A second DAS system was installed at a terminal further in the mainland of Country B, where it monitors 25 kilometers of both land and sea cable toward the first landfall point. This unit was deployed in a standardized rack solution provided by AP Sensing, ensuring seamless integration with the existing infrastructure. At the mainland terminal, SmartVision software collects and visualizes data from both DAS units, allowing the European TSO’s operators to access real-time insights via REST API and swiftly detect any potential issues.

Challenges

A key challenge in this project was the need for an extended measurement range beyond standard DAS capabilities. Monitoring 150 kilometers of submarine cable required a highly specialized approach, which AP Sensing addressed by implementing a range extender module. Additionally, early fault detection was critical to minimizing downtime and repair costs. Undetected events, such as cable damage or potential sabotage, could result in significant financial losses and operational disruptions, highlighting the necessity of a robust and reliable monitoring solution.

Benefits

By leveraging AP Sensing’s DAS technology, the European TSO gains enhanced visibility into the interconnector’s condition, enabling precise fault localization and faster response times. The system continuously collects and analyzes data, supporting operators in identifying anomalies that could impact power transmission. This insight minimizes the time and cost associated with locating and repairing faults caused by technical malfunctions, environmental factors, or external threats such as anchor strikes and fishing activities. During testing, the DAS system detected a controlled chain drag on the seafloor - 1.5 kilometers from the submarine power cable - and an anchor drop near the cable route. These events were precisely correlated with vessel AIS data, demonstrating the system’s accuracy and reliability. This capability is essential for safeguarding subsea infrastructure in high-risk areas prone to unintentional damage or deliberate sabotage.

Additionally, the DAS system supports regulatory compliance and strengthens grid resilience by enabling operators to swiftly identify and address operational risks. Remote monitoring significantly reduces the need for costly and time-consuming underwater inspections, offering a more efficient and data-driven approach to infrastructure management. This successful deployment has solidified the partnership between AP Sensing and the European TSO. With proven reliability and accuracy, plans are underway to expand DAS monitoring to the other end of the interconnector, further enhancing the security and reliability of this vital energy link.

Conclusion

With AP Sensing’s DAS technology, the European TSO has implemented an advanced, long-range monitoring solution for the interconnector, providing enhanced visibility into this critical power link. The system’s ability to support precise fault localization and proactive risk management ensures continuous protection of this essential infrastructure. This innovative approach enhances the reliability and safety of the interconnector while demonstrating the scalability and resilience of fiber optic sensing for large-scale energy projects. The project highlights how advanced sensing solutions can safeguard critical energy infrastructure and enable effective, data-driven decision-making. Together with the European TSO, AP Sensing is driving innovation and delivering technologies that address the complex demands of modern energy networks.