Project Overview

The Buk-Dangjin to Godeok underground power cable link supplies electricity in South Korea from the Dangjin power plant to Godeok, Pyeongtaek city and throughout the Seoul Metropolitan area. It is considered crucial in developing South Korea’s transmission network to meet the country’s rapid growth in energy demand. AP Sensing’s Distributed Acoustic Sensing (DAS) technology was recently deployed by Korean Electric Power Corporation (KEPCO) to monitor the power cable link.

The asset is a 500 kV HVDC transmission line, approximately 35 km in length. The underground power cable is installed with a burial depth varying from approximately 2 to 6 m in a special duct configuration. Due to the importance of the asset and high risk of damage posed by road construction activities along the transmission line, KEPCO decided to deploy AP Sensing’s DAS to monitor the asset and receive alerts in case of third party intrusion (TPI) activities. The project was led by GS E&C and supported by our partner, AP Technologies in South Korea.

Solution

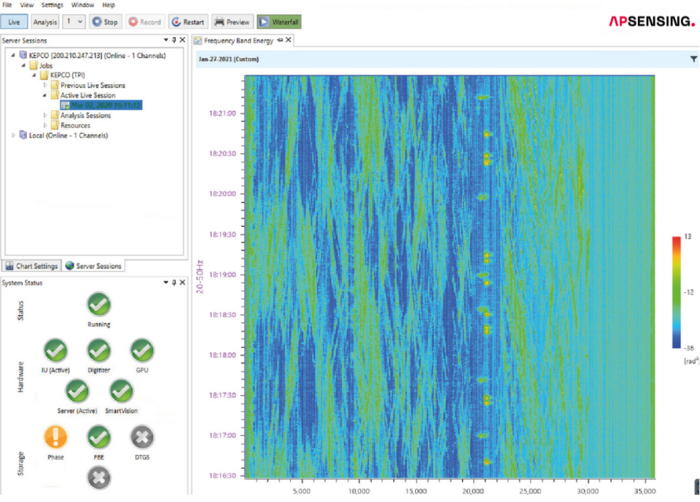

The monitoring system in this project consists of a one channel N5200A DAS instrument with a measurement range of 50 km, connected to a single-mode fiber within the fiber optic sensing cable, which is installed in the same duct configuration as the power cable. The DAS system is configured in order to monitor the transmission line in real time, visualize acoustic energy over time/distance in waterfall plots, and store the measured data on an external data storage unit with a total capacity of 96 TB. System alarms are triggered in the case of threatening construction activities on the roads above the power cable, and the DAS unit is mounted in a standard 19” cabinet that is installed at Godeok substation.

SmartVision

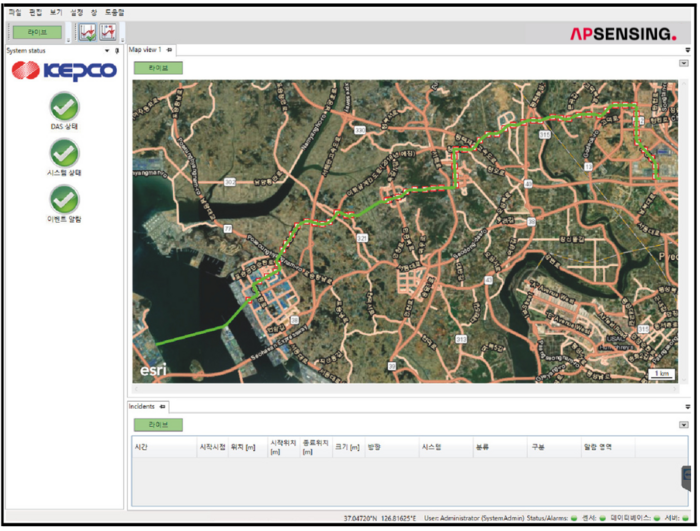

AP Sensing’s monitoring software SmartVision is installed on the main server, which is mounted in the DAS cabinet. A SmartVision client version is also installed on another PC, which is used to visualize the asset and the DAS alarms in Buk-Dangjin substation. In SmartVision, the MapView is implemented for visualization of the power cable route based on the corresponding GPS coordinates. The benefit of the MapView is to make locating a TPI event as simple as possible to the customer.

Conclusion

AP Sensing’s DAS system first passed a prequalification round based on a variety of different road construction activities, such as drilling, breaking, and collecting. The purpose of the tests were to simulate a real construction site which could take place on roads where the power cable is installed. The field tests were conducted successfully in 2016 in South Korea based on an actual section of the underground power cable using asphalt and concrete plates with different dimensions and distances to the cable.

After qualification of the DAS system, commissioning was conducted by mapping the sensing fiber to the asset, adjusting the acoustic zone values, and defining the alarm parameters. The final handover took place successfully at the end of 2020. To the satisfaction of the client, AP Sensing’s DAS has successfully been monitoring this important infrastructure since project commissioning.