Project Overview

EWA is the Electricity and Water Authority in Bahrain, focused on providing a quality, reliable electrical and water supply for sustainable development of the Kingdom of Bahrain. AP Sensing was recently selected to monitor a 400 kV power cable loop for EWA from Hidd to Riffa Grid Stations, located in the Kingdom of Bahrain. The power cable circuit includes a subsea section, and is monitored from both ends of the circuit. As part of EWA‘s strategic 400 kV Transmission Development program, this project adds a crucial link to the infrastructure of the Kingdom of Bahrain and is the first 400 kV XLPE submarine cable to be installed in the Gulf Cooperation Council (GCC) region.

Solution

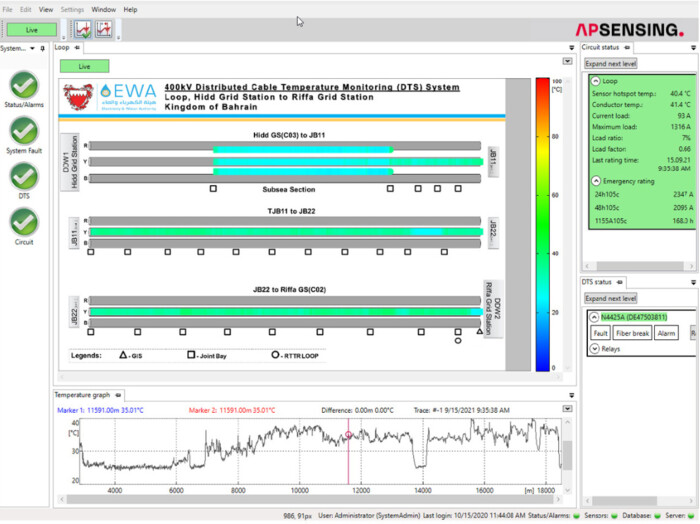

Two N4425A AP Sensing Distributed Temperature Sensing (DTS) devices were deployed in a single-ended configuration alongside SmartVision, AP Sensing‘s asset visualization software. Alarms are output via industry standard protocols (IEC 61850) used by the customer‘s SCADA system. Our DTS systems were selected in order to provide continuous temperature monitoring and asset protection, as well as power network performance optimization. The systems efficiently pinpoint cable failures and deliver operational status, condition assessment, and power circuit rating data (real time thermal ratting—RTTR/dynamic cable rating—DCR). Additionally, our technology identifies potential issues, such as hotspots and therma bottlenecks. Hotspots are particularly important to identify, especially at joint bays where a blast can occur in a worst case scenario. Power outages result in expensive repair costs and huge financial losses, which can easily be mitigated by continuous asset monitoring.

RTTR

RTTR/DCR provides predictive capabilities by continuously calculating the conductor temperature of a power grid by taking current load, load history, thermal conditions and other factors into account. At the same time it predicts the maximum permissible load for steady state ampacity and emergency ratings for emergency situations. Our RTTR seamlessly integrates into SmartVision.

SmartVision

AP Sensing‘s SmartVision asset viewer offers the client important circuit condition information in an easy-to-use graphical user interface (GUI). Temperature graphs and hotspot tables are readily available, and circuit layouts are mapped and color-coded to show the measuredd cable temperatures and indicate any instantaneous changes. Sections of the cable route can be individually defined for flexible alarm levels and types, while points of interest (cable joints, horizontal drillings, manholes) can be analyzed with historical trend analysis.

Conclusion

Deployed RTTR models as per industry standards (IEC 60287/60853) provide critical real-time information to operate both underground and subsea cable sections at highest safe current levels, taking into account the specific environment and different cable constructions/sizes for this project. After system installation, heat tests were conducted and the DTS quickly and accurately detected the position and temperature of hotspots. Due to the satisfying end result of this project, the client is currently deploying AP Sensing’s DTS technology on another 400 kV circuit – validating AP Sensing’s commitment to monitoring crucial infrastructures in the Gulf area, and exemplifying our strong and long-standing presence in the region.