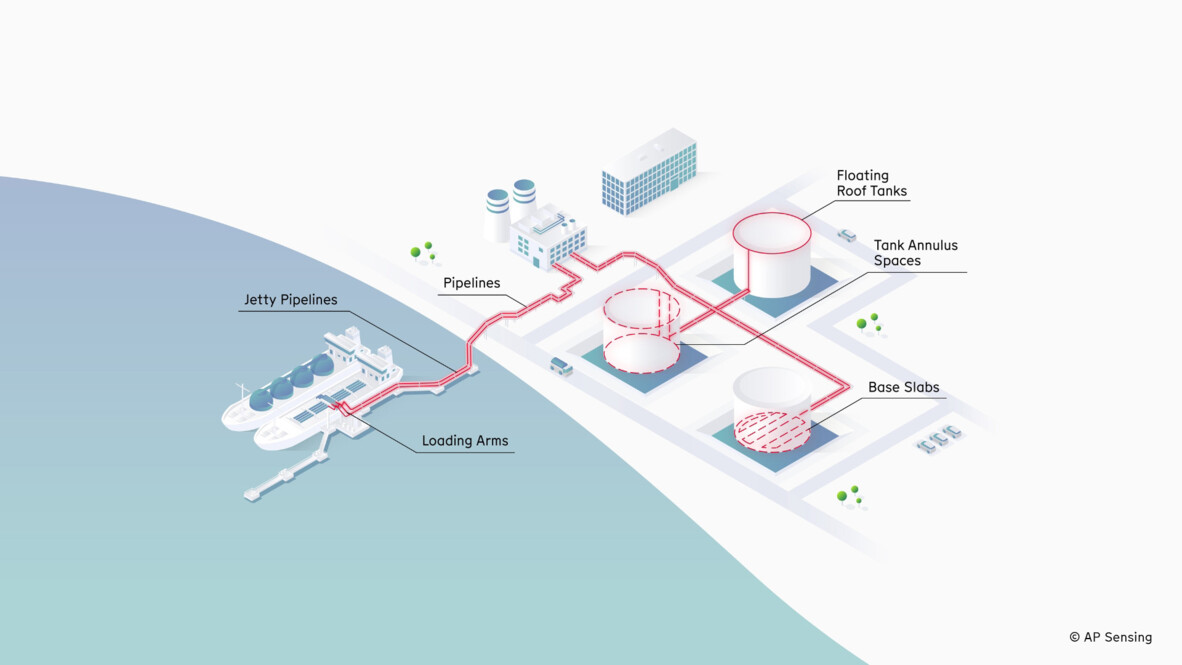

Distributed Fiber Optic Sensing (DFOS) is a cutting-edge technology to monitor and protect facilities managing liquefied natural gases (LNG) or other liquefied gases, such as LPG, ammonia, hydrogen and more. This innovative solution provides LNG terminal operators with the capability to monitor their entire infrastructure 24/7. By utilizing a fiber optic cable as a sensor, DFOS ensures the early detection and precise localization of leaks. Distributed Temperature Sensing (DTS) can quickly detect and locate even the smallest leaks, while also monitoring jetty pipeline cool-down and base slab heating.

AP Sensing's LNG terminal monitoring solution enables efficient leakage detection and gapless temperature monitoring to minimize risks at facilities managing LNG and other liquified gases, ensuring maximum safety and optimized terminal performance.

Understanding LNG Terminal Monitoring

Due to the extreme temperatures needed to keep gas in its liquid state, small leaks can have devastating consequences. Distributed Temperature Sensing (DTS) provides a linear temperature profile of assets by attaching a single fiber optical cable to the asset. The temperature information is analyzed in real time enabling efficient leakage detection while lowering cost of ownership and providing gapless temperature monitoring of the critical assets of an entire plant, such as pipes, tank annulus, impounding basins or pipeline jetties.

AP Sensing’s Monitoring Solutions

AP Sensing is your trusted partner for LNG & cryogenic applications with extensive experience in the monitoring of ammonia plants, regasification or liquefaction plants, and terminals. We listen to the challenges of EPC’s and integrators involved in the construction of LNG terminals and ammonia projects and strive to provide the best DFOS solution.

Our fiber optic Distributed Temperature Sensing solution is uniquely suited to a variety of monitoring tasks within any LNG facility, including:

- Impounding basins

- Base slabs

- LNG terminals (for re-gasification or transportation)

- Containments, foundations, pumps and piping

- Jetty pipelines

- Loading arms

- Tank annulus

- Floating roof tanks

- Pipelines

Event Detection

AP Sensing's solution detects and locates the following events:

- FOLDS – fiber optic leak detection system for detection/location of gases, water, liquid hydrocarbons, LNG, LGP, and multiphase pipelines

- Cool-down monitoring on the jetty

- Leakage detection in liquefaction and process areas

- Leakage monitoring in the tank annulus

- Monitoring of the spill containment area

- Tank annulus spillage monitoring

- Fire and hotspot detection in tanks, and throughout storage and processing facilities

Leak Detection

A leak of a pipe or tank leads to very low temperatures that are detected and precisely located within a few meters with the fiber optic sensor cable that is installed along the pipe, in the tank annulus or around impoundment basins. Various alarm thresholds can be individually set in different alarm zones offering pre- and main alarms. AP Sensing’s smart alarm features cover maximum, minimum and gradient alarms to ensure best performance. Our DTS solution offers the lowest false alarm rate in the industry; alarms are transmitted to the SCADA/DCS system through standard protocols like Modbus TCP and/or hard-wired relay contacts.

Tank Leak Detection and Spill Containment Areas

The sensor fiber is deployed in the annulus between the two tank walls during tank construction. If a leak occurs, cold or cryogenic fluids will cause a drop in temperature of the annulus space. Due to the low temperature of the fluid, the DTS system rapidly identifies even very small leaks with very low levels of false alarms.

Liquefied gas is also quickly detected by routing DTS sensor cable around the perimeter of the spill containment areas. When leaking material reaches the containment areas, the temperature decreases, triggering an alarm.

Base Slab and Pipeline Temperature Monitoring

The DTS monitors the entire pad area and heating system in real time, down to one-half meter spatial resolution. The sensor cable is deployed in the heating element conduit within the pad and provides temperature data every half meter along its path. In addition to monitoring functionality, the temperature data also minimizes power consumption. By identifying hot and cold spots, heating efficiency is improved. From the jetty to the process areas and on to the tanks: The AP Sensing DTS solution provides thermal gradient information during cool-down, ensuring that pipe stress is kept within specified limits. It also identifies pipe leak points and possible insulation problems that cannot be seen by a visual examination. Pipelines that transport liquefied gas, such as LPG, ammonium and hydrogen also benefit from the unique ability to quickly detect leaks and pinpoint them precisely. Thus, serious consequential damage can be reliably prevented.

AP Sensing’s DTS solutions are compliant with various regulations around the world. The operator receives all critical information, such as temperature, even for inaccessible locations inside the tank. Our system is certified for highly explosive atmospheres (ATEX/IECEx), and according to IEC 61508 SIL2. It is virtually maintenance-free and suitable for remote areas which are difficult to access. This ease-of-use comes with highly reliable performance, a low-power laser for safe use and a long product life . Part of our offer includes sensor cables that fit the needs of the application: robustness and a wide temperature measurement range.

Technology Used in LNG Terminal Monitoring

Distributed Temperature Sensing (DTS)

Distributed Temperature Sensing (DTS) technology is recommended for spillage detection in liquefied natural gas facilities in section 13.4 of EN 1473:2007-06. With optical fibers used for sensing, our system is non-corrosive and intrinsically safe in explosive atmospheres. It accurately measures the temperature over dozens of kilometers every minute and is also suitable for the operation under extreme conditions/in cryogenic conditions. With this real-time information, automatic countermeasures can be taken in the case of an emergency such as automatic system shut down, which minimizes human harm as well as environmental and economic consequences.

Our Innovative Software Solutions

SmartVision Software

Our sophisticated SmartVision software features asset visualization and alarm management with a central database plus reporting and analysis capabilities. The software’s intuitive graphic user interface (GUI) provides an overview of all critical assets and points of interest. Critical data is visualized, and the operator can identify the exact alarm trigger spot. Pinpointing multiple events simultaneously, the operator is enabled to react quickly and initiate appropriate countermeasures before severe damage and downtimes occur. SmartVision provides integration with other monitoring solutions, such as CCTV, DAS, DTS and other sensor solutions via standard protocols.

SmartVision features:

- Integrated management solution

- Asset visualization for complete plant overview 24/7

- Reporting and analysis capabilities

- Alarm management

- Central database

- Easy integration through flexible protocols and interfaces

Alarm Management

Basic thresholds for maximum temperature, temperature gradients, or differences to average temperatures enable the reliable protection of LNG Terminals. These parameters can be customized per detection zone depending on environmental conditions and expected critical thresholds.

Advantages of AP Sensing's Monitoring Solution

Compliance

AP Sensing understands your challenges and requirements. We are committed to defining well designed solutions that meet your safety requirements, whether you require ATEX Zone 0 compliance or need to be SIL-2 rated.

DTS technology is recommended for spillage detection in liquefied natural gas facilities in section 13.4 of EN 1473:2007-06.

- Accurate measurements not compromised by corrosive atmospheres or EMI

- Real-time temperature data along the entire passive optical sensor cable

- Long measurement reach, virtually maintenance-free for decades

- Easily installed in difficult access areas

- Instruments can be located in a remote-control room for safety compliance

Further Instrument Features

- ATEX certification down to Zone 0

- SIL-2 assessed by TÜV recognized consultants

- Proven field reliability with industry’s lowest maintenance and warranty costs

- Highest reliability throughout the entire operating temperature range

- Lowest laser output power—inherently safe in case of fiber breaks

- Wide range of industry standard communication protocols

With a proven track record and continued innovation, AP Sensing offers a completely integrated, end-to-end solution made in Germany. Our team works together with you to select the right combination of technologies to fit your requirements. We also provide onsite services, hotline and online support, maintenance and product training.

Find all our brochures, application flyer, product flyers, videos and further case studies in our media library.