Pipelines and LNG terminals are critical infrastructures where even minor incidents can lead to significant risks-threatening safety, disrupting operations, and causing costly damages. Monitoring these assets becomes increasingly complex under demanding conditions, where reliable, real-time insights are needed.

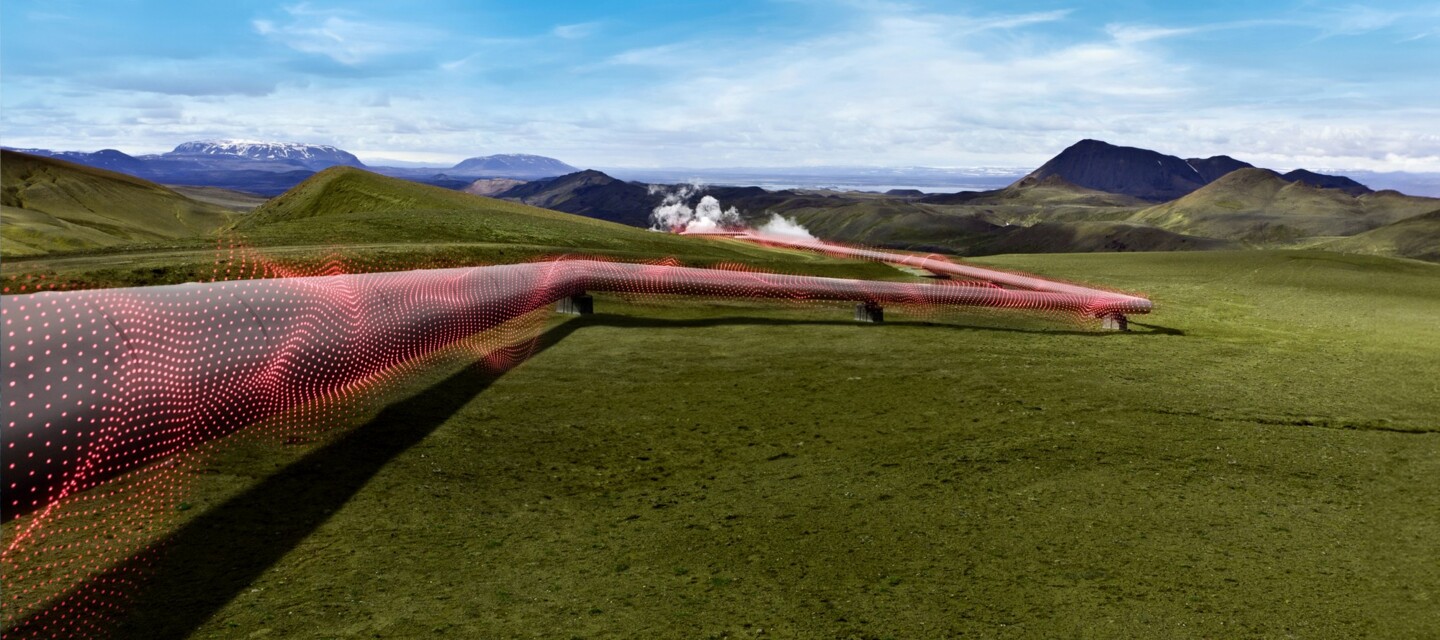

AP Sensing’s distributed fiber optic sensing technology provides a gapless pipeline monitoring solution for fast detection and accurate location of leaks and potential threats.

Understanding the Challenges

Pipeline operators and LNG terminal operators face unique and demanding challenges. Pipelines are often exposed to risks such as leaks, theft, third party intrusion (TPI), and structural stress, requiring continuous monitoring to ensure operational integrity and environmental safety. Additionally, identifying leaks or unauthorized activities over vast distances is complex and time sensitive.

For LNG terminals, handling cryogenic materials presents unique risks, including leaks in containment areas, thermal stress, and potential equipment failures. Ensuring safety during liquefaction, storage, and regasification processes is paramount.

Both industries require advanced, real-time, and non-intrusive monitoring solutions to enhance safety, minimize downtime, and comply with stringent safety and environmental standards. By addressing these challenges effectively, operators can protect assets, reduce costs, and improve operational efficiency.

AP Sensing's Monitoring Solutions

AP Sensing’s Distributed Fiber Optic Sensing (DFOS) technologies offer a reliable solution for comprehensive pipeline and LNG terminal monitoring. With thousands of installations worldwide, our advanced systems enable precise leak detection, real-time PIG Tracking, and intrusion detection, ensuring 24/7 protection for your critical assets. Designed for exceptional reliability and performance, our solutions safeguard operations, minimize risks, and reduce downtime in even the most challenging environments.

We deliver well-designed, comprehensive solutions for your challenges in pipeline protection.

Capabilities include:

- Pipeline leak detection and localization

- Third party intrusion (TPI)/intrusion detection system (IDS)

- Pipeline inspection gauge (PIG) tracking

- Ground movement detection

- Detection and localization of hotspots and cold spots

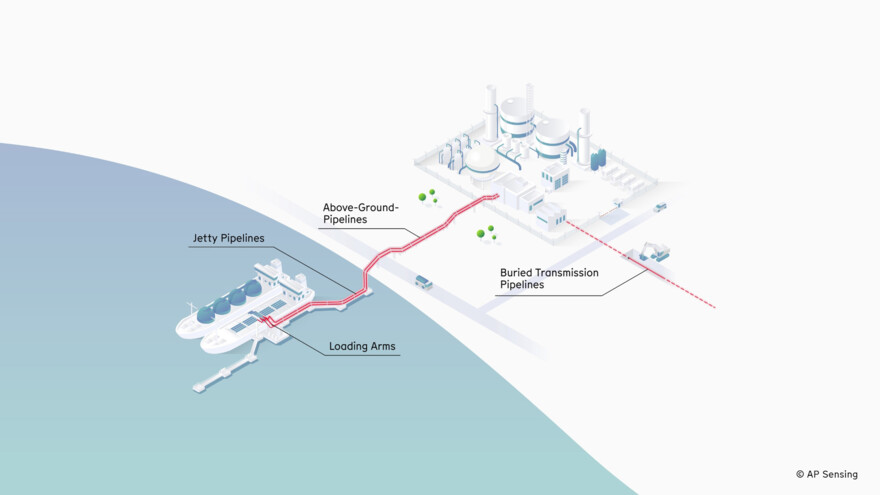

- Above-Ground-Pipelines

- Buried Transmission Pipelines

- Insulated Pipelines

- Block Valve Stations

- Jetty Pipelines

- Loading Arms

- Pipelines

- Floating Roof Tanks

- Tank Annulus Spaces

- Base Slabs

Pipelines

AP Sensing provides advanced monitoring solutions for a wide range of pipelines, including insulated thermal pipes, buried and above-ground pipelines, subsea pipelines, and those carrying crude oil, refined products, LNG, LPG, water, slurry, and cryogenic fluids. Our systems detect critical events such as leaks, ruptures, third-party interference, real-time PIG tracking, and flow constrictions due to liquid accumulations, hydrated formation or waxing. By ensuring precise event detection and continuous monitoring, we help you maintain safe and efficient pipeline operations. Read more here

LNG Terminals

With extensive experience in ammonia plants, regasification or liquefaction facilities, and transportation terminals, AP Sensing delivers reliable monitoring solutions for LNG and cryogenic applications. Our distributed fiber optic sensing technology is ideal for monitoring critical assets such as impounding basins, jetty pipelines, tank annuli, floating roof tanks, and pipelines.

Our solutions detect key events, including gas or liquid leaks, cool-down progress on jetties, spillage in tank annuli, and fire or hotspot formation in storage and processing areas. With precise event localization and continuous monitoring, we help ensure the safety and efficiency of your LNG operations. Read more here

Technologies Used in Process Automation & Pipeline Monitoring

AP Sensing’s pipeline and LNG terminal monitoring solution is based on three advanced technologies: Distributed Acoustic Sensing (DAS), Distributed Temperature Sensing (DTS) and Distributed Temperature & Strain Sensing (DTSS), These standalone technologies can also be combined to provide redundancy and fast leak alarm confirmation, ensuring comprehensive asset protection. Together, these technologies provide a robust, gapless monitoring solution for pipelines and LNG terminals, ensuring safety, reliability, and operational efficiency.

Distributed Acoustic Sensing (DAS)

DAS complements DTS by detecting leaks through noise, vibrations, and temperature changes associated with fluid escapes. It also enables real-time PIG tracking, identifying the progress and position of scrapers, weld interactions, and liquid accumulation. Additionally, DAS is effective for third party intrusion detection, identifying activities such as digging, pipeline drilling, or anchor dragging, as well as monitoring flow assurance.

Distributed Temperature Sensing (DTS)

DTS works by detecting and analyzing temperature variations along the pipeline. It identifies leaks by localizing hot or cold spots caused by escaping fluids. The pipeline is divided into zones to enable precise tuning and alarm thresholds for specific areas. This ensures accurate detection and localization of leaks.

Distributed Temperature & Strain Sensing (DTSS)

DTSS further enhances monitoring capabilities by detecting ground movement through strain measurement in the fiber optic cable. This makes it possible to identify potential risks to pipeline integrity caused by shifting terrain or structural stress.

Our Innovative Software Solutions

SmartVision Software

AP Sensing’s SmartVision management suite simplifies asset monitoring with a user-friendly graphical interface that integrates data from DAS, DTS, DTSS, CCTV, and other sensors into a single platform. Its advanced event visualization tools, including integrated maps, asset views, and waterfall diagrams, enable rapid decision-making and reduce response times by providing precise event locations.

Designed for seamless integration, SmartVision supports virtualized IT networks and interfaces easily with SCADA/DCS systems. With its proprietary SmartAlarm technology, the software delivers fast and reliable event classification, detecting even small leaks through advanced pattern analysis.

Alarm Management

SmartAlarm is designed to ensure Pipelines and LNG Terminals remain protected under various conditions. Basic thresholds for maximum temperature, temperature gradients, or differences to average temperatures enable reliable protection. These parameters can be customized per detection zone depending on environmental conditions and expected critical thresholds, ensuring a precise fit for each application.

Machine Learning Transient Alarm (MLTA)

Our machine learning transient alarm (MLTA) detects abnormal pipeline behaviors that would otherwise remain hidden within the temperature traces captured DTS systems. Our unique MLTA technique allows for the isolation of thermal transients along the monitored pipeline, enabling the detection of even small cold- and hotspots and triggering fast, reliable alarms.

Key Takeaways

- DTS, DTSS and DAS transform telecommunication fiber optic cables into sensing cables monitoring the entire pipeline

- Real-time and accurate data acquisition along the entire optical sensor cable

- The fiber is completely passive, immune to EMI, and non-intrusive

- Long measurement range, virtually maintenance-free for decades

- DTS, DTSS and DAS technologies are not influenced by the hydraulic conditions of the pipeline such as transients, slack flow or multiphase flow conditions

With a proven track record and continued innovation, AP Sensing offers a completely integrated, end-to-end solution made in Germany. Our team works together with you to select the right combination of technologies to fit your requirements. We also provide onsite services, hotline and online support, maintenance and product training.

Find all our brochures, application flyer, product flyers, videos and further case studies in our media library.