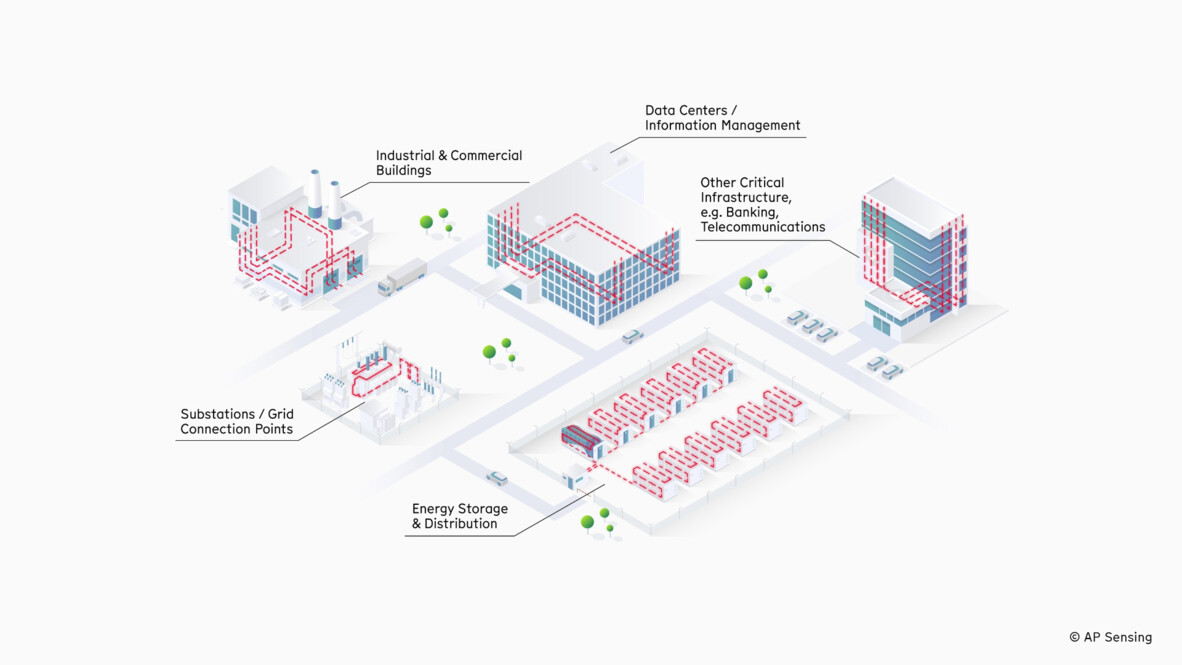

With the distribution grid serving as the backbone of the modern electrical power system, it plays a crucial role in delivering electricity to businesses and homes. Continuous monitoring is key to predictive maintenance, enabling 24/7 oversight of equipment for optimal performance and early issue detection. Minimize downtimes and enhance the reliability of your electrical power distribution system with fiber optic sensing. AP Sensing’s fiber optic Distributed Temperature Sensing (DTS) technology detects and locates hotspots, providing critical insights to prevent failures. Our solution addresses challenges in industrial and commercial buildings, energy storage systems, and data centers, offering continuous monitoring and early hotspot detection to reduce downtimes and enhance safety.

The Challenges

Facility managers seek assurance in the reliable operation of their electrical power distribution systems. Despite certifications, panel builder verification, and regular maintenance, switchgear and busbars remain susceptible to failure and malfunction. Power-handling devices dissipate energy as heat, particularly under complex, unpredictable loads, increasing the risk of issues at critical points such as loose joints. Traditional thermography surveys, while common, are often time-consuming and limited by accessibility constraints in modern facilities. This presents a growing challenge in large buildings where rapid temperature rise in bus ducts can lead to overheating, requiring more frequent and effective monitoring to prevent failures and outages.

Continuous Bus Duct Temperature Monitoring

Fiber optic sensing technology allows for real-time temperature monitoring of bus ducts, addressing the limitations of traditional methods. This advanced monitoring system not only detects temperature fluctuations promptly, but also offers a proactive approach to identifying overheating and potential damage.

Unlike other electrical systems that lack built-in monitoring capabilities, bus ducts equipped with fiber optic sensors eliminate the need for retrofitting discrete sensors or relying on frequent thermal imaging services, which can be expensive and time consuming.

Moreover, the technology provides a comprehensive and continuous monitoring solution, ensuring that even inaccessible or hidden areas within assets are effectively observed, minimizing the challenges associated with traditional monitoring systems, particularly in managing large electrical currents.

AP Sensing's Solution

AP Sensing’s Distributed Temperature Sensing (DTS) technology offers a comprehensive, cutting-edge solution to address additional monitoring needs for electrical systems. Our continuous monitoring solution complies with the NFPA 70B guideline by supporting predictive maintenance and enhancing system reliability, thus meeting the standard’s requirements for proactive, condition-based electrical maintenance.

Continuous Busbar Temperature Monitoring

CBTM for bus ways, bus ducts and bus bars provides 24/7 measurement, alarming, reporting, and recording of the bus bar temperature.

Continuous Switchgear Temperature Monitoring

CSTM provides a simple, effective solution for monitoring all switchgear with a single DTS system, enabling automated, remote and 24/7 monitoring.

Continuous Generator and Transformer Monitoring

CGTM allows safe operation at high loads and critical times, without risking asset failure which would result in severe damage to the transformer, generator or backup battery, unscheduled downtimes, high repair costs, and loss of revenue.

Continuous Rack Temperature Monitoring

CRTM detects and locates hotspots and other disruptive conditions which could otherwise result in overheating, which significantly reduces or eliminates the need for manual testing and inspection.

HVAC Assets, Storage and Drainage Vessels

HVAC assets, storage and drainage vessels benefit from 24/7 temperature monitoring, and sewage and drainage may also be continuously monitored for early leak detection in order to prevent outages, pinpoint hotspots, and ensure environmental compliance and operational efficiency.

Distributed Temperature Sensing (DTS)

DTS technology comprises a head-end unit and a long length of fiber optic sensor cable that can reach all points of interest (POI) within the asset. The sensor cable (highlighted in red) is an ordinary fiber optic cable, terminated on the DTS head end, and can be up to 10 km in length per channel. It is important to note that this sensor cable is dielectric and passive and can therefore be used in the vicinity of bare metal busbars.

Increased electrical resistance due to loosened connections or overheating can lead to significant operational issues, such as equipment damage and power supply interruptions, particularly in semiconductor manufacturing and data centers.

DTS offers permanent consistent temperature measurements, with updates every minute. It precisely pinpoints the location of hot spots, identifying the exact POI, and seamlessly integrates with building management systems (BMS) and supervisory control and data acquisition (SCADA) systems by industry-standard communication protocols.

Hotspot alarms are presented through BMS/SCADA interfaces or via standard IT techniques, ensuring that end-users are automatically informed of detected hotspots and their exact locations. With flexible alarm schemes, users can set static, gradient, and average alarm thresholds, ensuring early detection of issues. Typically, each DTS unit terminates at least four sensor channels.

For electrical applications, a passive, dielectric sensor cable is advantageous, as it is capable of handling temperature peaks of up to 150 °C and only one sensor cable is required to reach all points of interest within the asset, up to 10 km in length. The sensor cable may be directly fitted onto bare metal bus bars or within high-power density systems; AP Sensing offers patented accessories for secure and reliable cable installation.

Expanding Our Monitoring Solution

SmartVision for Predictive Maintenance

AP Sensing’s SmartVision asset visualization software provides a comprehensive, state-of-the-art overview of your electrical assets, including easily accessible temperature profiles and alarms, recording of events for playback and in-depth analysis, aggregation of alarms and interfacing with BMS/SCADA systems via Modbus which facilitates quick responses to issues, support of multiple operator consoles, and upstream communication via SMS over SMMP for additional convenience.

The data collected by SmartVision enables the implementation of appropriate action to mitigate potential issues.

AI and Machine Learning

AI and Machine Learning are transforming the way bus duct monitoring is conducted, offering advanced tools beyond analyzing and predicting system performance. As power consumption patterns evolve and new methods of power generation emerge, switchgear manufacturers now provide various instrumentations to measure and record key electrical parameters. AP Sensing integrates these technologies with real-time data collection, enabling platforms with AI and Machine Learning capabilities. This approach allows for more intelligent monitoring, optimizing system reliability and efficiency. By deploying Distributed Fiber Optic Sensing (DFOS) for temperature monitoring, operators can harmonize distributed power generation and improve overall grid management.

Advantages of AP Sensing's Monitoring Solution

- 24/7 continuous monitoring

- Early detection of hotspots

- Precise location of issues

- Reduced downtimes

- Improved safety

- Cost-effective maintenance

Our DTS solution is thoroughly tested, with the most complete set of certifications on the market (VdS, UL, FM, ATEX, IECEx, SIL) and a 35 year MTBF. It is robust and has passed highly demanding type testing.

The sensor cables are passive, immune to electromagnetic interference (EMI), resistant to dirt and dust, and virtually maintenance-free. They are also proofed for high temperatures and dielectric strength, ensuring the DTS system can withstand the demands of temperature monitoring.

At AP Sensing, we’re committed to providing comprehensive and cutting-edge solutions for CBTM and other electrical monitoring applications. Our technology ensures the reliability and safety of your electrical assets, preventing costly downtime and disruptions. We offer an integrated, end-to-end solution and our team works together with you to select the right combination of technologies to fit your requirements. We also provide onsite services, hotline support, maintenance, and product trainings.

Find all our brochures, application flyer, product flyers, videos and further case studies in our media library.