The future of energy requires green, renewable sources to meet growing demand. At the same time, grids must ensure greater connectivity and stability through smart technologies. This is a challenge for power grids, which already need to operate at the highest possible safe ampacity level today.

To protect valuable power cable infrastructure, high safety margins are often applied. These can limit the efficiency of your power cable infrastructure. AP Sensing is the Distributed Temperature Sensing (DTS), Distributed Acoustic Sensing (DAS) and Distributed Temperature & Strain Sensing (DTSS) solution provider for your power grid. Our power cable monitoring solution balances the need for asset protection and power network performance optimization by efficiently pinpointing the root causes of cable failures and potential bottlenecks.

Understanding Power Grid Monitoring

As energy demand grows and the shift toward renewable sources accelerates, power grids require greater interconnectedness and stability supported by smart technologies.

Power grid operators face the challenge of balancing efficiency with safety and reliability. Operating at the highest possible safe ampacity levels requires careful monitoring to avoid overloading and potential failures. Comparing current loads with planning estimates helps operators determine how much the steady-state load can be safely increased. Managing peak loads and emergencies is another challenge, particularly in identifying critical sections of exposed or shallowly buried sea cables, which can become vulnerable points in the network.

Holistic cable condition monitoring offers the technological edge needed for the safe and reliable transmission and distribution of electricity.

AP Sensing's Monitoring Solutions

AP Sensing's Distributed Fiber Optic Sensing (DFOS) solutions for temperature, strain and acoustic measurements give you the ideal solution to monitor and protect your power infrastructure.

Our unique technology ensures gapless and real-time temperature and acoustic measurements along the entire power circuit. It precisely localizes hot spots and cable faults, computes the actual ampacity, predicts emergency rating hours in advance, and estimates e.g. the burial depth of sea cables. With our sensing solutions you receive maximum network performance under safe operational conditions.

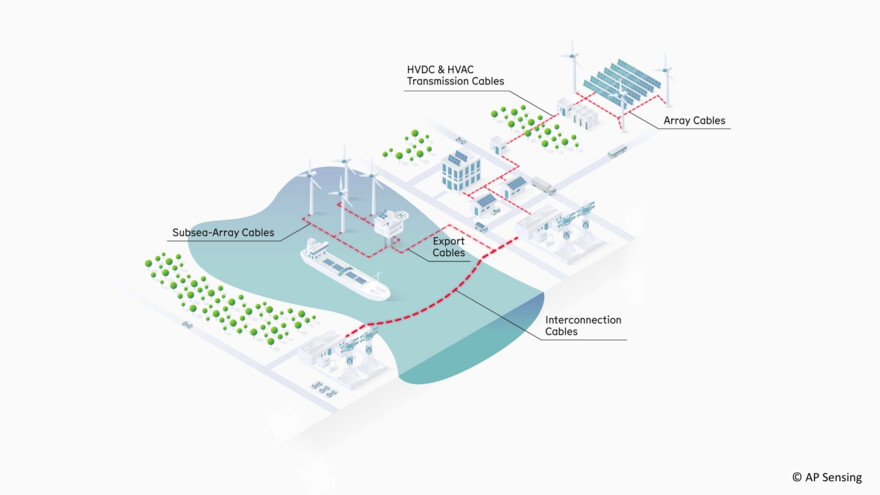

We deliver well-designed, comprehensive solutions for your challenges and applications, including:

- HVDC / HVAC transmission cables

- Underground power cables

- Distribution cables

- Industrial and commercial buildings

- Data centers / information management

- Substations / grid connection points

- Energy storage & distribution

- Other critical infrastructure (e.g. Banking, Telecommunications)

Monitoring Parameters and Applications in Power Grid

Underground Cables

Underground cable monitoring is crucial for maintaining reliability and preventing failures caused by environmental and mechanical threats. Advanced technologies like Distributed Temperature Sensing (DTS), Distributed Temperature & Strain Sensing (DTSS) and Distributed Acoustic Sensing (DAS) play a key role in enhancing early fault detection and optimizing maintenance strategies. Read more

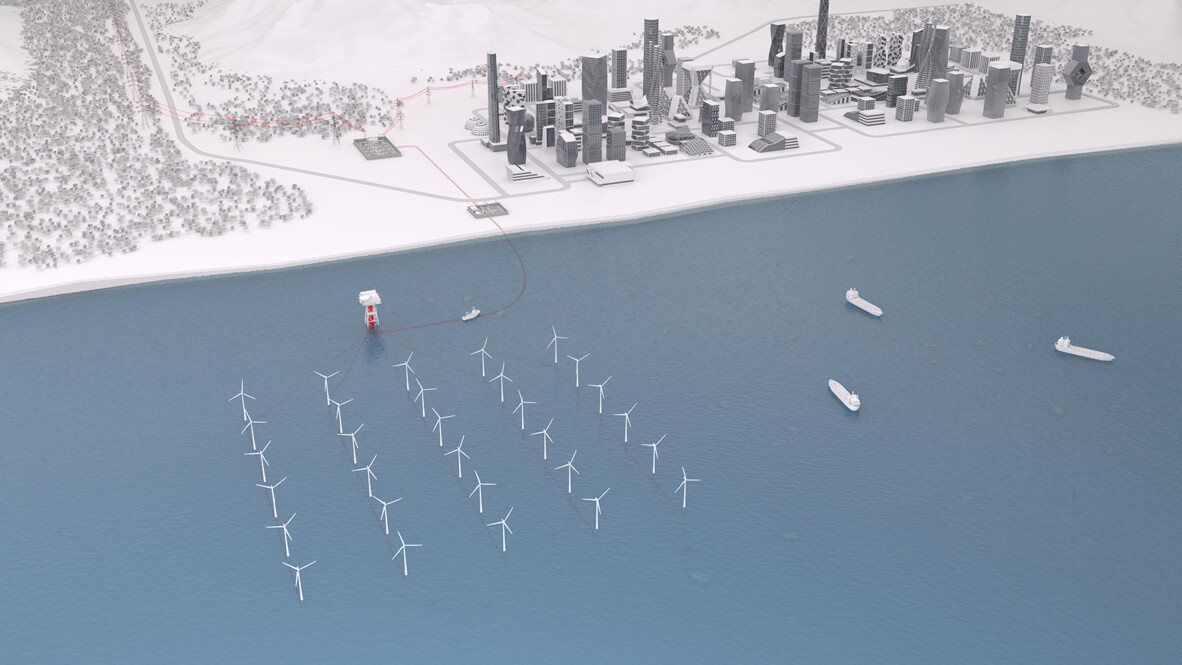

Subsea Cables

There are approximately 1.4 million kilometers of active submarine cables worldwide. Monitoring these subsea cables is essential for maintaining the reliability and efficiency of underwater power transmission systems. AP Sensing’s DFOS solutions enhance fault detection, thermal performance, and the security of subsea cables. Read more

Bus Duct Systems

With the distribution grid serving as the backbone of the modern electrical power system, it plays a crucial role in delivering electricity to businesses and homes. Continuous monitoring is key to predictive maintenance, enabling 24/7 oversight of equipment for optimal performance and early issue detection. Minimize downtimes and enhance the reliability of your electrical power distribution system with distributed fiber optic sensing. Read more

Technologies Used in Power Grid Monitoring

Distributed Temperature Sensing (DTS)

Distributed Temperature Sensing (DTS) is crucial in power grid monitoring. It provides continuous temperature monitoring of power cables, detecting hotspots and thermal bottlenecks, delivering operational status, condition assessment and power circuit rating data (RTTR/ DCR) .

Distributed Acoustic Sensing (DAS)

Distributed Acoustic Sensing (DAS) offers accurate cable fault detection and location, as well as third party intrusion (TPI) protection both onshore (e.g. cable theft, digging and drilling) and offshore (e.g. anchor drops and drags). Providing efficient power cable condition monitoring by listening 24/7 to acoustic signatures, DAS helps you optimize transmission line and distribution networks, while reducing operational costs along the entire asset.

Distributed Temperature & Strain Sensing (DTSS)

Distributed Temperature & Strain Sensing (DTSS) enables continuous monitoring of both temperature and mechanical strain along power cables, detecting thermal anomalies, mechanical stress, and potential cable damage. It provides real-time insights for condition assessment, operational integrity, and power circuit rating (RTTR/DCR) , enhancing grid reliability and predictive maintenance.

Expanding Our Monitoring Solutions

Fiber-based Current Monitoring (FbCM)

AP Sensing’s Fiber-based Current Monitoring (FbCM) expands the functionality of our DAS technology with the option of electrical condition monitoring. Sheath currents of AC power cables are indicators for the functionality of bonding, insulation failures, link box flooding, unwanted ground contacts and sheath damages resulting from third party intrusions (TPI). AP Sensing’s FbCM can detect all those issues in real-time.

SmartVision Software

AP Sensing's SmartVision management suite shows the condition of your circuits at a glance, controlled by an easy-to-use graphical user interface (GUI). It seamlessly integrates many DAS, DTSS, DTS, CCTV and other sensors into a single platform. Circuit layouts are mapped and color-coded to show the measured cable temperatures, as well as instantaneous changes in acoustic energy. Temperature graphs and hotspot tables are readily available. Sections of the cable route can be individually defined for flexible alarm levels and types. Points of interest, such as cable joints, horizontal drillings and manholes can be analyzed with historic trend analysis and historical data is always accessible.

Machine Learning Transient Alarm (MLTA)

Additionally, our Machine Learning Transient Alarm (MLTA) detects abnormal asset behaviors that would otherwise remain hidden within the temperature traces captured DTS systems. Our unique MLTA technique allows for the isolation of thermal transients along the monitored asset, enabling the detection of even small cold- and hotspots and triggering fast, reliable alarms.

Real-Time Thermal Rating (RTTR)

Real-time thermal rating (RTTR) or dynamic cable rating (DCR) continuously calculates the conductor temperature of a power grid by taking current load, load history, thermal conditions and other factors into account. At the same time it predicts the maximum permissible load for steady state and emergency situations. Based on industry standards IEC 60287, IEC 60853 and finite element modeling, you can operate your network at the highest possible safe ampacity levels with excellent predictive capabilities.

Depth of Burial State (DoBS)

For subsea cables, a Depth of Burial module (DoB) can be integrated into the SmartVision software platform to calculate the Burial Depth of the cable. DoB changes are identified along the cable, enabling significant cost savings. In addition, exposed subsea cable segments can be detected and countermeasures initiated.

We comply with industry standards including ISO 9001, ISO 14001, ISO 45001, and ISO 27001 for cyber security.

With a proven track record and continued innovation, AP Sensing offers a completely integrated, end-to-end solution made in Germany. Our team works together with you to select the right combination of technologies to fit your requirements. We also provide onsite services, hotline and online support, maintenance and product training.

Find all our brochures, application flyer, product flyers, videos and further case studies in our media library.