A blazing fire can have devastating consequences, posing risks to human life, damaging valuable infrastructure and assets, and causing prolonged downtimes. Fire protection becomes even more complex in environments affected by harsh conditions, where conventional solutions often fall short. AP Sensing’s fiber optic Linear Heat Detection (LHD) is an ideal solution for monitoring special hazard applications in challenging environments, such as traffic tunnels, PV installations, parking garages, or in the manufacturing industry ensuring both safety and operational continuity.

Challenges & Opportunities

Industrial facilities frequently generate dirt, dust, humidity, and corrosive atmospheres during production, storage, or transport, making conventional sensor technologies prone to failure and nuisance alarms. These nuisance alarms can lead to costly interruptions, such as shutting down production lines, tunnels, and, in the worst cases, activating high-cost fire suppression systems like deluge or high-expansion foam. Safety systems in these environments require the earliest and most reliable fire detection, especially in larger facilities that involve complex installation, commissioning, and higher maintenance demands.

Fiber Optic LHD as a Solution for Fire Detection

AP Sensing's fiber optic Linear Heat Detection (LHD) technology offers an ideal solution for fire protection in special hazard applications and challenging environments. Our approved technology uses a fiber optic cable as a precise, distributed heat sensor, reliably detecting fires even in facilities exposed to harsh conditions. It provides accurate temperature profiles every few seconds along the fiber optic cable, covering distances of several thousand meters.

AP Sensing's Linear Heat Detection System

Our LHD N45-Series is thoroughly tested and certified (EN (VdS), UL, ULC, FM, KFI, SIL2, IECEx, ATEX) with the industry's fastest fire detection and lowest false alarm rate.

The LHD N45-Series withstands even the harshest conditions like:

- Dirt, dust and corrosive atmospheres

- High humidity and frequent temperature changes

- Solvent vapors and detergents

- Electromagnetic interference (EMI)

- Explosive environments due to gas or dust (ATEX / IECEx)

Application Fields of Fire Detection

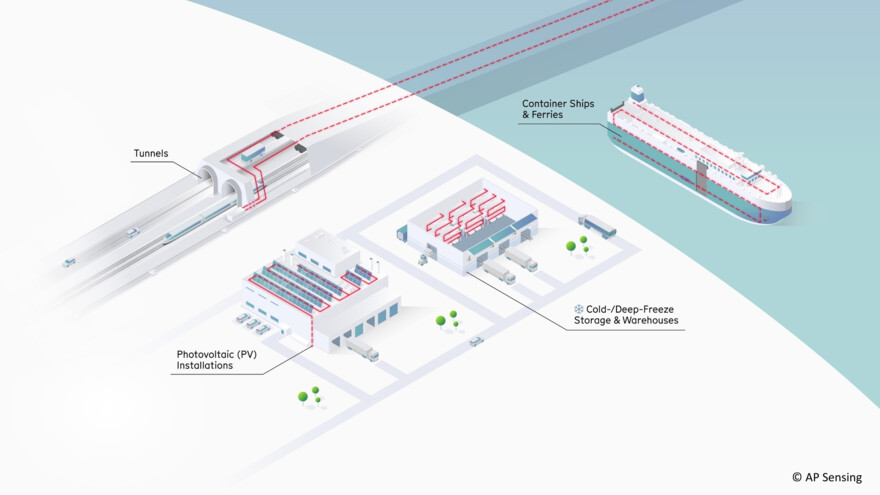

Our technology extends into areas that other detection technologies (e.g. smoke, heat or flame detection) are unable to reach, providing coverage in environments, such as:

- Transportation Sector

Road and rail tunnels, metro stations, parking garages and aircraft hangars - Production & Storage Facilities

Coal storage, battery storage and warehouse facilities, conveyor belts and production areas, tank farms, food industry, refineries and chemical plants, false floors and ceilings - Energy Sector

Photovoltaic systems, battery storage, cable trays and transformers - Ships & Vessels

Container ships & ferries

- Tank farms, coal storage

- Production areas

- Food industry

- Power plants

- Refineries and chemical plants

- Warehouses and freezers

- Conveyor belts

- Cable trays and transformers

- Photovoltaic (PV) installations

- Battery energy storage systems

Advantages of Our LHD N45-Series for Fire Detection

A fiber optic LHD system is designed to monitor and detect changes in temperature along the entire length of a passive fiber optic sensor cable. This allows our LHD solution to detect abnormal temperature changes and fires quickly and to precisely identify their location.

Maximum Safety and Protection for Your Assets

Our fire detection system, the LHD N45-Series, is unaffected by air currents and hence accurately determines the location, the size and direction of a spreading fire. No other fire detection system can withstand temperatures up to 750 °C (1400 °F) for 2h without losing monitoring capability. With AP Sensing’s LHD solution, fire-fighting countermeasures can be used effectively before and throughout the fire event.

Ideal for Large-Scale Infrastructures

In large-scale infrastructures the 4mm diameter fiber optic sensor cable typically runs through different areas under various temperature conditions. The LHD N45-Series lets you configure the appropriate and individual alarm criteria in hundreds of zones along the same cable run. Depending on customers’ requirements in the project, the zones along the sensor cable can have different lengths, can partially or fully overlap or allow for gaps for transit between two areas of interest. The system is immune to dirt, dust, corrosive environments, organic vapors or explosive atmospheres. AP Sensing’s solutions include certified sensor cables for cost-sensitive, standard or specialized applications. All cables have an expected lifespan of 30 years and are virtually maintenance-free.

SmartVision Software: Easy Integration and Superb Insight for Operators

AP Sensing's SmartVision software provides a visual overview of alarm zones, operational status, and real time temperatures at a glance, controlled by an easy-to-use graphical interface (GUI). Monitored assets and facilities are mapped and color-coded to show the measured temperatures, alarm zones and fire locations, as well as fire size and spreading. This ensures that personnel responsible for emergency situations have an immediate, accurate overview on a single screen. SmartVision allows for custom-defined alarm zones and seamlessly integrates multiple sensors, such as Distributed Acoustic Sensing (DAS), DTS, CCTV, and more, into a single platform.

Key Takeaways

- A single passive Ø 4 mm sensor cable, easy to install

- Immune to EMI, dirt, dust and humidity

- Maintenance-free, longest lifetime

- Largest coverage

- Functional even at 750 °C for 2 h according to IEC 60331-25

- Precise location of multiple fire events

- Fire size and spread monitoring

- Five different alarm criteria for quick detection in all 2,000 zones per channel

- Flexible zone and alarm configuration

With a proven track record and continued innovation, AP Sensing offers a completely integrated, end-to-end solution made in Germany. Our team works together with you to select the right combination of technologies to fit your requirements. We also provide onsite services, hotline and online support, maintenance and product training.

What is important when selecting a fiber optic LHD system? Is it wrong to equate measurement time with response time? How many channels are optimal for your configuration?

Find all our brochures, application flyer, product flyers, videos and further case studies in our media library.