Effective well and reservoir monitoring is essential for maximizing production efficiency and ensuring the longevity of resources. The evolution of fiber optic sensing technologies – such as Distributed Temperature Sensing (DTS), Distributed Acoustic Sensing (DAS), and Distributed Strain Sensing (DTSS) – plays a crucial role in optimizing oil and gas upstream operations. These advanced sensing solutions provide the capability to monitor downhole conditions with precision, even in challenging environments.

Advanced Monitoring Solutions for Upstream Oil and Gas Applications

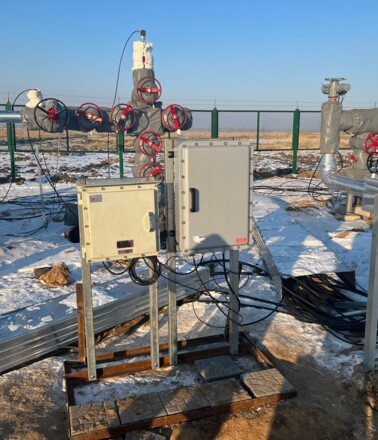

With over a decade of experience, AP Sensing has successfully deployed its systems across various regions, addressing the unique demands of the oil and gas industry. Our solutions are designed to ensure the integrity of critical infrastructures, by enabling real-time data collection and analysis.

The implementation of our fiber optic sensing technologies enhances resource management and operational safety, allowing for proactive responses to potential issues. As we continue to innovate and adapt our offerings, AP Sensing remains committed to delivering reliable solutions that support the evolving needs of the oil and gas upstream sector.

Understanding Oil and Gas Monitoring

Fiber optics is essential in modern oil and gas operations due to its ability to deliver real-time, continuous monitoring across various critical applications:

- For well integrity and equipment monitoring, fiber optics detects early signs of issues such as casing deformation or equipment malfunctions, ensuring safe and efficient operations.

- In production monitoring, it provides precise data that supports the optimization of production processes and enhances recovery effectiveness.

- During hydraulic fracture monitoring, fiber optics tracks microseismic activity and fracture propagation, improving fracture design and effectiveness.

- For enhanced oil recovery (EOR) projects, it offers detailed insights into fluid injection and reservoir response, supporting more effective recovery strategies.

- In borehole seismic applications, fiber optics provides valuable data for seismic monitoring, enabling accurate detection of subsurface geological changes and seismic events, which enhances the understanding of reservoir dynamics and optimizes exploration and production activities.

Overall, fiber optics enhances safety, efficiency, and productivity in oil and gas operations.

Key Advantages

Today's oil and gas upstream operations require real-time, continuous downhole monitoring to achieve optimal economic performance while addressing health, safety, and environmental (HSE) risks. Fiber optic installations in boreholes provide a powerful solution, tackling some of the key industry challenges:

Early Issue Detection for Failure Prevention

Monitoring well performance, including well integrity and equipment status, is crucial for detecting issues early and preventing costly failures. Early detection helps optimize maintenance schedules, reduce downtime, and extend the overall life of well infrastructure.

Enhacement of Operational Efficiency

Timely interventions and informed decision-making improve recovery rates and reduce downtime. Fiber optic systems enable continuous monitoring, offering real-time insights into reservoir behaviour. By combining real-time data with long-term monitoring insights, engineers can make strategic decisions to enhance operational efficiency and prolong the productive life of wells.

Reducement of Operational Costs

Fiber optic monitoring provides precise, continuous data that optimizes resource management and enhances safety, ultimately reducing costs and improving the industry's economic and environmental sustainability.

Achievement of Net-Zero Emissions

As global efforts to address climate change accelerate, fiber optic sensing technology emerges as a valuable tool to help minimize carbon footprints. By enabling early detection of well integrity issues—often overlooked by conventional tools—fiber optics helps prevent environmental concerns before they arise.

Mitigation of HSE Risks

Fiber optic sensing provides real-time monitoring of critical parameters such as temperature, pressure, vibration, and strain across various assets. This proactive approach detects anomalies such as leaks, structural weaknesses, or equipment malfunctions early, preventing hazardous incidents. It safeguards workers, reduces exposure to dangerous substances, and protects the environment.

AP Sensing's Distributed Fiber Optic Solution

AP Sensing’s DFOS technology is a well-established technology for various downhole applications. It offers significant advantages, including the ability to perform multiple measurement types – such as temperature, acoustic, and strain – using a single cable with multiple fibers. This enables simultaneous, real-time measurements along the entire wellbore, enhancing reservoir understanding and supporting proactive responses to safety concerns, while reducing environmental impact and operating time. Our solution provides 24/7 continuous, gapless monitoring.

Unlike conventional production monitoring systems, our DTS, DAS and DTSS technologies are highly effective in identifying differential reservoir depletion, cross-flow between reservoir layers, and other near-wellbore effects. The continuous optical fiber leaves no area unmonitored. With a single passive fiber optic cable, our systems provide thousands of measurement points along the asset, enabling intelligent completions with continuous downhole monitoring and flow control.

Our solutions offer robust and reliable asset protection for various application areas, including:

Technologies Used in Oil & Gas Upstream Monitoring

Distributed Temperature Sensing (DTS)

AP Sensing’s DTS is based on the proven Raman optical time domain reflectometry technology (R-OTDR). AP Sensing uses its patented code correlation OTDR (CC-OTDR) that allows utilization of low optical power. It eliminates any problems with laser degradation and enables worry-free, long-term measurement stability.

AP Sensing’s DTS solution provides real-time wellbore temperature data, offering operators a precise and continuous view of well conditions. By monitoring temperature profiles and trends over time, it enables operators to track well performance, optimize production, and monitor wellbore integrity and artificial lift systems 24/7. The system also allows for the evaluation of long-term reservoir responses, helping to maximize production efficiency.

Key Features:

- Multimode and single-mode instruments

- Single-/dual-ended configurations

- Longest measurement range of up to 70 km

- Spatial resolution of 0.5 m, measurement time down to 1 sec

- Modern, easy-to-use web interface for easy set-up and system configuration

- Wide operating temperature range from -10 to +60 °C

- Low power consumption

- DTS traces export in *.csv, *.witsml, *.las formats

- Laser Class 1M with low optical output for safe operations

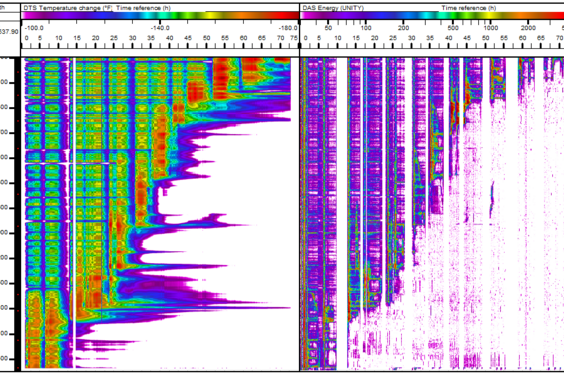

Distributed Acoustic Sensing (DAS)

AP Sensing’s phase-based DAS system measures the acoustic vibrations on the fiber based on the principles of coherent optical time domain reflectometry (C-OTDR). The revolutionary 2P Squared technology of DAS provides a true linear measurement of dynamic fiber length changes caused by strain from acoustic/vibration signals or temperature fluctuations.

The DAS system captures acoustic data from individual zones, identifying abnormal patterns and providing real-time insight into well and reservoir conditions. This enables proactive maintenance. DAS effectively detects leaks, small flow changes, and flow behavior across the entire wellbore. DAS also generates flow data at each point along the asset and processes historical data for comprehensive monitoring. By delivering accurate measurements of frequency, phase, and amplitude, DAS helps mitigate potential site risks through early detection of various anomalies.

Key Features:

- The true, phase-based system allows for quantitative data interpretation

- Configurable gauge length

- Leading performance with standard fiber without additional amplification

- Performance tests based on SEAFOM recommendations

- Modular edge computing for real-time process optimization

- Laser Class 1 with low optical output for safe operations

Distributed Temperature Strain & Sensing (DTSS)

AP Sensing’s DTSS is based on the Brillouin optical time-domain reflectometry (BOTDR) technology. BOTDR operates with a large optical budget on a single-ended fiber, being less affected by changes in fiber attenuation. BOTDR enables extensive and accurate measurements of both temperature and strain within the sensing range.

Key Features:

- Single-ended design – no loop required

- 80 km + measurement range with multiple internal optical channels

- High optical budget ensures outstanding measurement performance

- Practical and user-friendly web interface for easy commissioning

- Resistant to hydrogen darkening of optical fibres in harsh downhole environments

- Laser Class 1M with low optical output for safe operations

Our Innovative Software Solutions

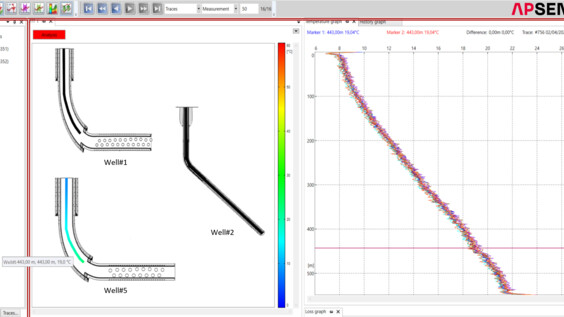

SmartVision

AP Sensing's SmartVision suite shows the condition of your well and reservoir at a glance, controlled by an easy-to-use graphical user interface (GUI). It seamlessly integrates many technologies, such as DAS, DTS and other sensors into a single platform. Alarms are shown on the screen in an emergency situation, and the operator is directly informed about the location of the critical incident. Temperature graphics and hotspot tables are readily available.

Drawing on our HP (Hewlett-Packard) heritage in optical test leadership, we have established ourselves as the leading solution provider for distributed optical sensing. We remain committed to delivering well-designed, comprehensive solutions.

PLATO-DTS

PLATO-DTS, developed by Interpretive Software Products (ISP), is designed to visualize and interpret DTS data from any well in order to obtain production and injection profiles. PLATO-DTS uses an enthalpy balance model that accounts for heat transfer due to both conduction and convection of temperature. Frictional heating, Joule-Thompson cooling, skin effect, and phase changes that contribute to temperature changes are naturally predicted by the model. With added features to optimize DTS data, from visualization to permanent monitoring, PLATO-DTS is the standard in the industry when it comes to temperature modelling.

Key Features:

- An extended dynamic database that allows over 15,000 traces to be imported into one PLATO project

- Various DTS data visualization modes, including curves, animation, color gradients, depth cross-plots, and station plots

- Quantitative production/injection profiling using probabilistic modelling (Global Optimization)

- Intended for production, injection, shut-in wells and capable of handling complex geometries

- Reliable results in fractured wells during warmback (fracking) and flowback (Geotherm Automation)

- Suitable for permanent well monitoring

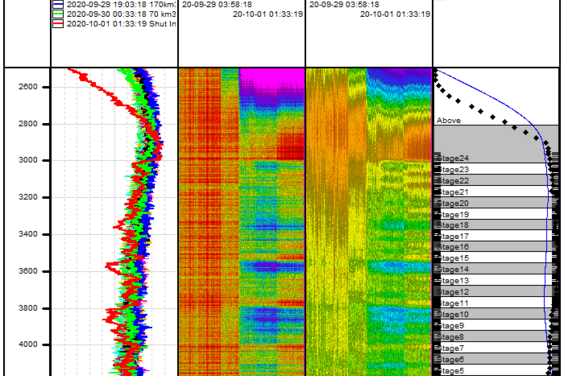

ARIANE-SP2S

ARIANE-SP2S, developed by Interpretive Software Products (ISP), enables real-time DFO data processing and offers unlimited, multi-scale, high-definition visualization. ARIANE-SP2S is a comprehensive solution for DAS monitoring which dynamically displays any acquisition duration in real-time without any limitations.

Key Features:

- Frequency Band Energy plots (FBEs) and Spectrum on-site extraction in real-time from AP Sensing DAS acquisition systems for well monitoring

- Data storage reduction by a factor of 8,000

- In-depth visualization and qualitative analysis

- Direct synchronization of DAS and DTS data

- Advanced time and depth scrolling and zooming capabilities

- Easily extendable for data visualization of Distributed Pressure Sensing, Distributed Strain Sensing, and Distributed Chemical Sensing

- Remote monitoring without supervision enabled

Key Takeaways of DFOS Value in O&G Upstream Monitoring

- Well Integrity and Well Equipment Monitoring: Whether a temporary or permanent installation, immediate detection of well integrity issues.

- Production Monitoring: complementing conventional production logging tools (PLT) or as a standalone method for quantitative assessment of production profile.

- Sand Production Control: by using DAS, detection, localization, and quantification of the sand amount being produced. This helps to optimize production, improve targeting of remedial actions, and minimize equipment damage.

- Hydraulic Fracturing: monitoring, evaluation and optimization of hydraulic fracture operations.

- Seismic Monitoring: Using DAS for seismic monitoring (borehole and surface), enabling high-resolution imaging of subsurface structures. This supports more accurate reservoir characterization and enhances decision-making for field development and exploration.

With a proven track record and continued innovation, AP Sensing offers a completely integrated, end-to-end solution made in Germany. Our team works together with you to select the right combination of technologies to fit your requirements. We also provide onsite services, hotline and online support, maintenance and product training.

Find all our brochures, application flyer, product flyers, videos and further case studies in our media library.