Towards a Net-Zero Future: Why CCS is Essential for Our Climate Goals

In the journey towards a greener and more sustainable energy future, transitioning from traditional fossil fuel sources to renewable alternatives is crucial. Alongside efforts to reduce emissions, adopting carbon removal technologies has become increasingly vital. Carbon Capture and Storage has emerged as a pivotal solution in addressing the global challenge of climate change.

CCS plays a critical role in climate mitigation by capturing CO2 emissions from the atmosphere. The Intergovernmental Panel on Climate Change (IPCC) and International Energy Agency (IEA), alongside various other entities, emphasize the critical significance of CCS in achieving net-zero emissions by 2050.

Overcoming Challenges in Carbon Capture and Storage

The CCS process involves three key stages:

- Capturing CO2 emissions from sources such as fossil fuel power plants, industrial facilities, and natural gas processing plants.

- Transporting them through pipelines to the storage location.

- Safely storing them underground in deep geological formations such as saline aquifers or basalt formations.

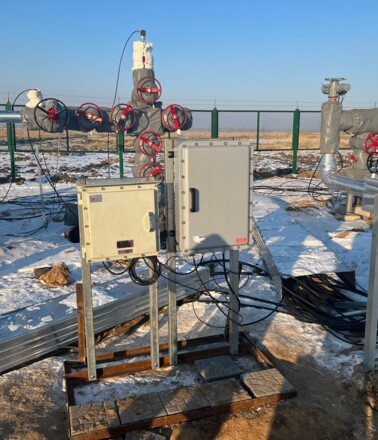

Effective monitoring is essential to ensure storage site integrity, prevent leaks, and verify that CO2 remains securely contained. Many monitoring technologies, initially developed for the oil and gas sector, can be adapted for carbon storage projects. One notable technology is Distributed Fiber Optic Sensing (DFOS), which offers continuous insights into the CO2 injection process and the storage environment due to its distributed measurement capabilities.

The Importance of Monitoring CO₂ Injection and Storage

Effective monitoring of CO2 throughout its journey – from transportation to injection and long-term storage – is essential to ensuring the safety and success of CCS projects. During transportation, tracking CO2 movement in pipelines helps identify any leaks or pressure changes, ensuring safe delivery to storage sites.

At the storage site, monitoring CO2 injection is crucial for addressing potential well integrity issues and preventing the migration of CO2 plumes outside designated storage areas. Technologies such as DFOS play a vital role in tracking the behaviour of injected CO2, enabling early detection of anomalies or leaks. Continuous assessment of the storage site with DFOS helps identify anomalies or leaks early, mitigating risks and enhancing the overall safety and effectiveness of CCS projects.

AP Sensing's Advanced Solution for CCS Monitoring

AP Sensing's DFOS is a well-established solution successfully adapted for various downhole applications, now being transferred to the CCS applications and offering following advantages:

Accuracy and Real-Time Insights

DFOS offers unparalleled accuracy and real-time insights, allowing for the tracking of carbon dioxide plume movement and the identification of potential disturbances associated with leaks or microseismic events. This proactive monitoring optimizes operational parameters and addresses issues before they escalate.

Comprehensive Approach

AP Sensing's DFOS technology strategically embeds fiber optic cables within carbon capture infrastructure, creating a comprehensive network of sensors that perform multiple types of measurements simultaniously – including temperature, acoustic, and strain, which helps to identify possible leaks throughout the entire system. This capability enables simultaneous, real-time monitoring along the entire wellbore, enhancing reservoir understanding and supporting proactive responses to safety concerns. By minimizing environmental impact and reducing operational time, DFOS supports effective management of CCS projects.

24/7 Safety

Our solution delivers 24/7 continuous, gapless monitoring of CO2 injection and plume behavior. As a valuable complement to conventional monitoring systems, our technologies – Distributed Temperature Sensing (DTS), Distributed Acoustic Sensing (DAS), and Distributed Temperature Strain Sensing (DTSS) – are particularly effective in monitoring CO2 injection and CO2 plume dynamics within the reservoir. The continuous optical fiber ensures that no area is left unmonitored, providing thousands of measurement points along the asset with a single passive fiber optic cable, enhancing overall monitoring capabilities and supporting effective decision-making.

Technologies Used in CCS Monitoring

Distributed Temperature Sensing (DTS)

AP Sensing’s DTS is based on the proven Raman optical time domain reflectometry technology (R-OTDR). AP Sensing uses its patented code correlation OTDR (CC-OTDR) that allows utilization of low optical power. It eliminates any problems with laser degradation and enables worry-free, long-term measurement stability.

AP Sensing’s DTS solution provides real-time wellbore temperature data, offering operators a precise and continuous view of well conditions. By monitoring temperature profiles and trends over time, operators can track the CO2 injection process and monitor wellbore integrity 24/7.

Key Features:

- Multimode and single-mode instruments

- Single-/dual-ended configurations

- Longest measurement range of up to 70 km

- Spatial resolution of 0.5 m, measurement time down to 1 s

- Modern, easy-to-use web interface for easy set-up and system configuration

- Wide operating temperature range from -10 to +60 °C

- Low power consumption

- DTS traces export in *.csv, *.witsml, *.las formats

- Laser Class 1M with low optical output for safe operations

Distributed Acoustic Sensing (DAS)

AP Sensing’s phase-based DAS system measures the acoustic vibrations on the fiber based on the principles of coherent optical time domain reflectometry (C-OTDR). The revolutionary 2P Squared technology of DAS provides a true linear measurement of dynamic fiber length changes caused by strain from acoustic/vibration signals or temperature fluctuations.

The DAS system captures acoustic data from individual zones, identifying abnormal patterns and providing real-time insight into well and reservoir conditions. DAS effectively detects leaks, small flow changes, and flow behavior across the entire wellbore. DAS also generates flow data at each point along the asset and processes historical data for comprehensive monitoring. Additionally, DAS plays an important role in seismic applications, including vertical seismic profiling (VSP) and surface seismic monitoring, enhancing subsurface imaging and the understanding of CO2 plume behaviour. By delivering accurate measurements, DAS helps mitigate potential site risks through the early detection of various anomalies.

Key Features:

- The true, phase-based system allows for quantitative data interpretation

- Configurable gauge length

- Leading performance with standard fiber without additional amplification

- Performance tests based on SEAFOM recommendations

- Modular edge computing for real-time process optimization

- Laser Class 1 with low optical output for safe operations

Distributed Temperature Strain Sensing (DTSS)

AP Sensing’s DTSS is based on the Brillouin optical time-domain reflectometry (BOTDR) technology. BOTDR operates with a large optical budget on a single-ended fiber, being less affected by changes in fiber attenuation. BOTDR enables extensive and accurate measurements of both temperature and strain within the sensing range.

Key Features:

- Single-ended design – no loop required

- 80 km + measurement range with multiple internal optical channels

- High optical budget ensures outstanding measurement performance

- Practical and user-friendly web interface for easy commissioning

- Resistant to hydrogen darkening of optical fibres in harsh downhole environments

- Laser Class 1M with low optical output for safe operations

Key Takeaways of DFOS Value in CCS Monitoring

- Well Integrity Monitoring: Early detection of well integrity issues that may lead to undesired CO2 migration.

- CO2 Injection Monitoring: Acquiring temperature warm-back data to quantify the CO2 injection profile and ensure safe containment.

- Seismic Imaging: Using DAS for both borehole and surface seismic monitoring, providing high-resolution imaging of subsurface structures and enabling precise CO2 plume tracking underground.

With a proven track record and continued innovation, AP Sensing offers a completely integrated, end-to-end solution made in Germany. Our team works together with you to select the right combination of technologies to fit your requirements. We also provide onsite services, hotline and online support, maintenance and product training.

Find all our brochures, application flyer, product flyers, videos and further case studies in our media library.