Successful rail operation requires a balanced approach that prioritizes continuous innovation, sustainable investments, energy efficiency, optimal capacity and traffic management, and enhanced safety measures. Continuous railway monitoring solutions like fiber optic sensing, which require no trackside equipment, provide significant advantages over traditional typically point systems dependent on additional infrastructure. This opens new possibilities for addressing the key success factors of modern railway operations.

Real-time monitoring of trains and track conditions enables the early detection of issues such as equipment failures or unauthorized access, allowing for rapid response and preventing costly disruptions.

By integrating fiber optic sensing technology, railway operators can optimize maintenance schedules, improve energy efficiency, and increase the capacity of existing rail infrastructure. As rail networks expand and digitalization continues, comprehensive monitoring solutions are essential for ensuring the safe, reliable, and efficient operation of railway systems worldwide.

Mitigating the Risks of Railway Operations

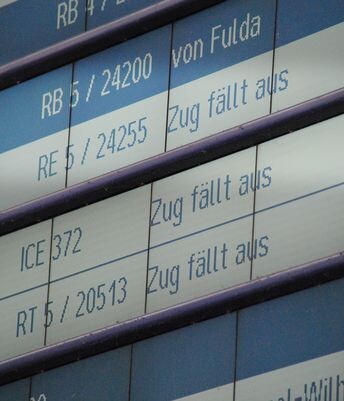

Railway networks face various threats that can disrupt operations and compromise railway safety. Issues such as track faults, equipment failures, and environmental hazards like landslides or flooding can lead to significant delays or accidents. Additionally, third party intrusion (TPI)—including vandalism, intrusions, and cable theft—poses serious risks to the system’s integrity. Implementing real-time railway monitoring helps identify and resolve these issues before they escalate, enhances rail safety, protects critical infrastructure, and increases the efficiency of railway operations.

Optimizing Railway Operations With Real-Time Monitoring

AP Sensing offers advanced Distributed Fiber Optic Sensing (DFOS) technology that provides continuous real-time rail monitoring. Our system accurately detects train movements independently from trackside equipment, locates potential issues such as track faults, track condition changes, intrusions, and equipment failures, enabling operators to respond quickly and prevent costly disruptions.

By delivering precise information on train location, speed, and direction, AP Sensing’s solutions optimize traffic flow and allows improved train dispatching better energy efficiency and support predictive maintenance. This comprehensive monitoring approach utilizing the same hardware enhances both railway safety and operational efficiency.

Key Areas We Cover

Our solutions monitor critical areas of railway infrastructure, including:

Rolling Stock Monitoring

- Train tracking

- Location, speed, and direction (even underground or in tunnels)

- Integrity, including the number of cars, bogies, and overall length

- Detection of significant wheel defects like flats and riffle

- Real-time derailment detection

Rail Infrastructure Monitoring

- Track condition monitoring

- Changes of condition

- Changes of track ballast dynamics

- Rail Defect Detection (e.g. rail breaks, ripple, cracks)

- Below Ballast Scan (assess the condition and stability of the ballast layer beneath railway tracks)

- Overhead contact line/catenary flashover localization

- Vandalism detection (cable theft)/third party intrusion (TPI)

- Natural hazard detection (rockfall, landslide, tree fall)

- Railroad crossing monitoring (trespassing detection, traffic management optimization)

- Continous fire detection (most suitable in linear assets such as tunnels, cable ducts or railway stations)

Driving continuous improvement and innovation across all applications and features, many of these capabilities have already proven their reliability and effectiveness through rigorous field testing. Others are being actively optimized and tested to ensure they meet the precise operational demands of railway applications.

The Technology Behind Advanced Railway Monitoring

AP Sensing’s Distributed Acoustic Sensing (DAS), Distributed Temperature Sensing (DTS), and Distributed Temperature & Strain Sensing (DTSS) technologies form the foundation of our advanced railway monitoring solutions using fiber optic sensor cables.

Technologies Used in Railway Monitoring

Distributed Acoustic Sensing (DAS)

Our DAS system continuously detects real-time acoustic signals along tracks, providing precise information on train location, speed, and potential hazards such as intrusions or equipment failures. Powered by our 2P Squared technology—which processes both phase and power measurements—our system delivers highly accurate and stable signal detection over long distances, ensuring reliable performance even in challenging environments.

Distributed Temperature Sensing (DTS)

Our DTS system continuously monitors temperature, enabling early detection of heat or fire within tunnels, cable ducts and other infrastructure.

Distributed Temperature & Strain Sensing (DTSS)

AP Sensing’s Distributed Temperature and Strain Sensing (DTSS) technology provides critical insights into the structural health of railway infrastructure, including bridges, tunnels, and tracks. Using Brillouin-based Optical Time Domain Reflectometry (OTDR), DTSS continuously monitors temperature and strain changes along fiber optic cables, precisely detecting anomalies such as mechanical stress, structural shifts, and thermal variations.

Ideal for railway monitoring, DTSS enables early detection of risks like landslides, track deformations, and tunnel instability, enhancing safety and minimizing disruptions. Immune to electromagnetic interference and requiring minimal maintenance, DTSS offers a cost-effective, reliable solution for proactive railway infrastructure management.

SmartVision Software

Both DAS and DTS integrate seamlessly into SmartVision, our asset visualization and data management platform. SmartVision™ consolidates real-time data from multiple sensors, providing operators with a clear overview of the railway network, including asset condition, and environmental status. This integration helps optimize railway operations, improve safety, and support predictive maintenance strategies.

Why Choose AP Sensing for Railway Monitoring?

- Real-Time Detection: Immediate identification of track faults, intrusions, and environmental hazards ensures quick responses and minimizes disruptions.

- Increased Safety & Efficiency: By enabling predictive maintenance and optimizing traffic flow, our solutions reduce accidents, improve energy efficiency, and increase network capacity.

- Comprehensive Asset Protection: Continuous monitoring protects infrastructure from wear, theft, and vandalism, ensuring long-term reliability.

With a proven track record and continued innovation, AP Sensing offers a completely integrated, end-to-end solution made in Germany. Our team works together with you to select the right combination of technologies to fit your requirements. We also provide onsite services, hotline and online support, maintenance and product training.

Find all our brochures, application flyer, product flyers, videos and further case studies in our media library.